Delta Energy Storage Solution Improves Power Supply Stability

Delta Energy Storage Solution Improves Power Supply Stability

at Taipower’s Kinmen Xiaxing Power Plant

Delta's energy storage solution was successfully introduced at Taipower's Kinmen Xiaxing Power Plant, which is currently the largest energy storage system owned by Taipower. Delta’s role in completing the system covered all aspects from planning, and manufacturing to construction and on-site testing.

This now provides a new power dispatching tool for Taipower's grid. In daily operations, the system regulates the frequency of the power grid and renewable energy, thereby improving power supply stability. In the event that a temporary backup emergency power supply is needed, the system can provide instantaneous power within only 200 ms.

Generator response speed and renewable energy makes power dispatching a challenge

Stabilizing power supply quality is critical for power companies. The complexity of large power systems is problematized by the fact that any abnormality or equipment failure will affect stability and reliability.

When an instantaneous load increase or decrease occurs with traditional diesel generators, the frequency correction speed is relatively slow, and poor responsiveness may result in an accident. In addition, renewable energy is subject to large power fluctuations and uncontrollable factors, and the influence such problems can have on power supply stability should not be underestimated. This poses a significant challenge as the proportion of renewable energy integrated into the grid grows, especially in closed grids such as at Kinmen.

To solve these problems, energy storage systems are the best tool for dispatching and regulating. Such systems can not only regulate the frequency and store excess renewable energy, but they can also reduce the load pressure on online generators by instantly supplying power when a generator trips.

However, whether energy storage systems can operate effectively at critical moments, power company owners must carefully consider various performance conditions. These include power control function, system configuration, response speed, safety mechanisms, and solution integrity.

Backup support with continuous regulation and quick response enhances power supply stability

Kinmen is an island county at the west of Taiwan. It consists of Kinmen Island and other large and small islands. Its power supply system is not connected to Taiwan’s main island and has always faced the challenge of large frequency fluctuations. Moreover, there is a considerable difference in the power load across the island’s infrastructure, and the power consumption gap between winter and summer can reach 35 MW.

In addition to Tashan, Xiaxing, Kirin, and other diesel power plants on the island, the county government has also carried out a low-carbon plan to install wind and solar power stations so as to fully leverage natural resources.

The Kinmen power plant is equipped with 16 sets of diesel power generating units, some of which are used for auxiliary purposes. However, because the auxiliary units are not all under a hot engine state, they may fail to respond once an operating unit trips, meaning that they cannot supply power immediately. In severe cases, a chain reaction may occur, which can disconnect operating units and cause a power outage over a large area.

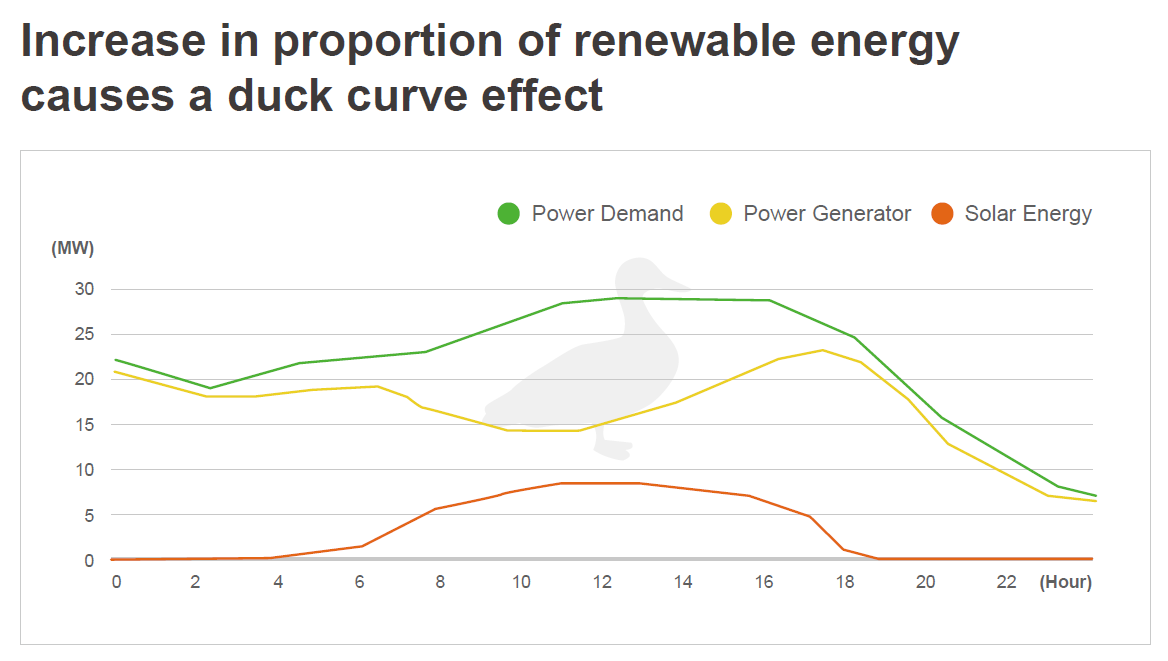

Implementing continuous renewable energy is one of Kinmen's development directions. However, renewable energy is subject to the “duck curve” effect, which is the result of solar energy being sufficient during the day but absent during the night. This means that traditional generators can lower their load during the day but need to raise their output immediately to fill the power demand gap at night. As the proportion of renewable energy increases annually, the duck curve effect will become more obvious. If there is no flexibility in frequency regulation and power dispatching, this will place considerable pressure on system reliability.

To stabilize the frequency, reduce the impact of fluctuations in renewable energy, and configure a backup power source that can respond quickly, Taipower decided to implement an energy storage system at Xiaxing Power Plant in Kinmen and setup an energy management system (EMS) at Tashan Power Plant for remote monitoring.

The solution had to meet the following conditions:

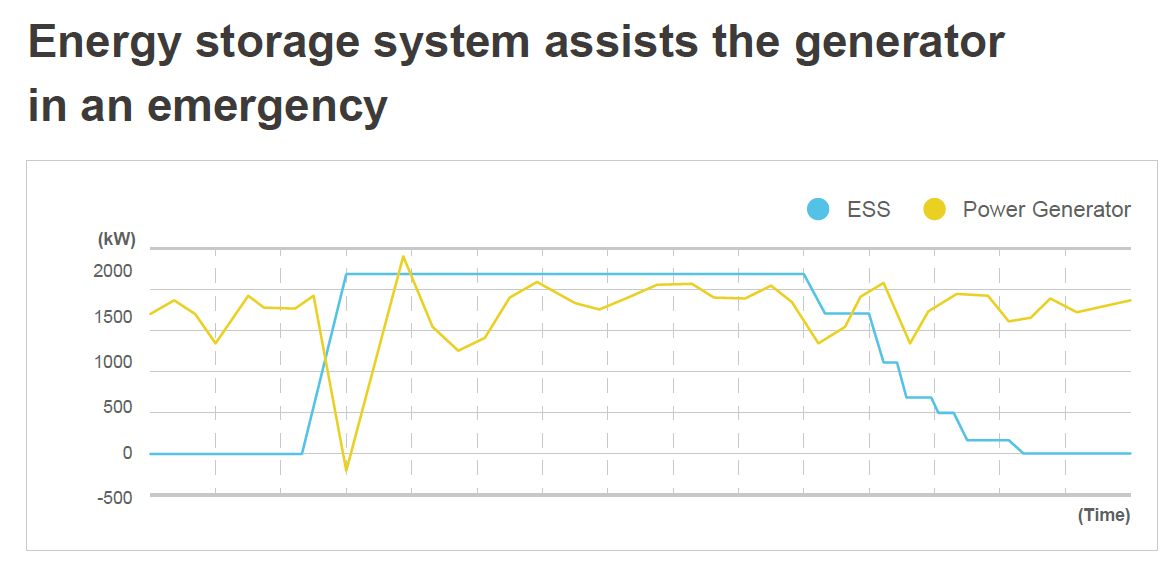

․When a trip event occurs, the system must run at full load within 400 ms so as to immediately supply power;

․When a trip event occurs, the system needs to provide 2 MW of power for at least 30 minutes, allowing for sufficient restart and dispatch time to connect offline units;

․The battery in the energy storage system must have appropriate protection mechanisms in place;

․Management software should be provided with a Chinese user interface to shorten the learning curve and facilitate daily control;

․The system should comply with IEC international standards to ensure the safety of equipment and staff.

One-stop solution highly integrated PCS, battery, environmental control, and management software

Delta's energy storage solution integrates a power conditioning system (PCS) container consisting of two 1-MW utility-grade PCSs, a battery energy storage system (BESS) container with 1 MWh of total usable storage capacity of lithium batteries, self-developed EMS, and other peripheral power devices such as step-up transformers.

The solution not only met the requirements of the Xiaxing Power Plant, but also allows supervisors to purchase all required hardware and software products at once. A single service window simplified communication and maintenance complexity, speeding up the completion of the project.

The PCS1000 installed in a 20-ft container is a megawatt bi-directional PCS responsible for controlling, converting, and regulating power. It has automatic voltage and frequency regulation, active/reactive power compensation, anti-islanding detection, islanding control operation mode, virtual synchronous generator (VSG) control, and other functions. More importantly, this PCS allows the energy storage system to complete the detection operation within 200 ms, thereby responding quickly to supply output power. This response speed is double the 400 ms required for the project.

Another important part in the solution is the BESS, which uses domestically produced high-power P140 lithium batteries. It can instantly output a large amount of power due to the discharge rates of 2C -4C . The 40-ft container contains 462 battery modules with a total storage capacity of more than 1,000 kWh. Accompanied by a battery management system and FM200 automatic fire suppression system, it can provide a multi-level safety protection mechanism to ensure safe operation through monitoring, proactive notification, and remote control.

Additionally, the project involved implementing a building management solution to ensure the durability of the container in outdoors, monitor the hydrogen concentration, eliminate fire concerns, and provide automated management and control. To manage air conditioning, lighting, and fire prevention in the container while detecting the water accumulation, the system uses real-time control instead of manual operations. These features ensure that the system container remains properly maintained in an optimized operating environment.

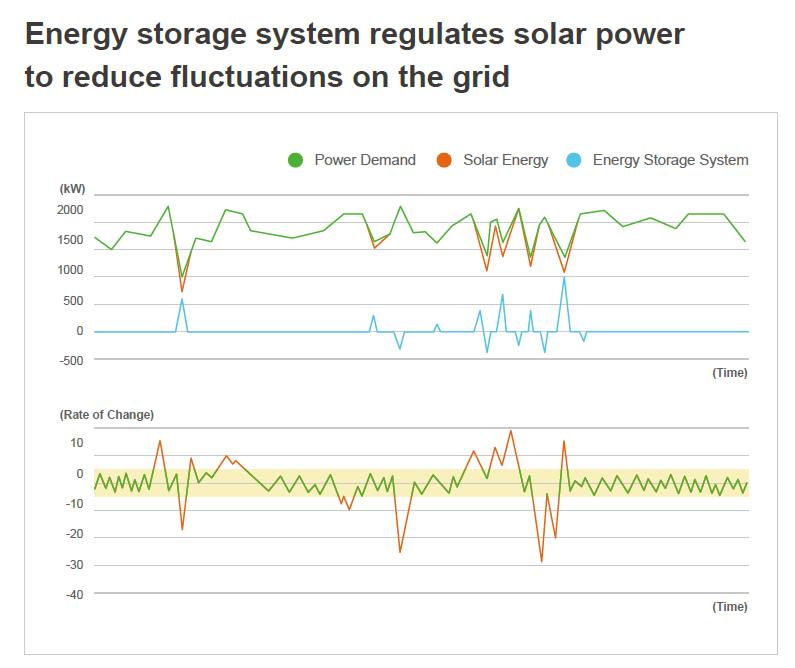

Delta’s energy storage system provides a variety of functional modes, enabling users to set the required operating mode via a web interface. The system also allows concurrent dual-mode operation. For example, it usually runs in F–P (Frequency–Watt) mode to regulate the frequency of the power grid to avoid excessive variation; meanwhile, it is also in the real-time RoCoF (Rate of Change of Frequency) detection state.

In the event of an emergency where the speed or amplitude of the frequency exceeds the set threshold, the system automatically activates a tripping mechanism and delivers 2 MW of power to the power grid within 200 ms at full load, giving power plant staff valuable buffer time to remedy abnormal conditions. Until the generating units can stably supply electricity and the power grid returns to normal, the energy storage system would gradually reduce the load and withdraw from the grid according to the Taipower dispatch steps. The system returns to F–P mode and continues to operate after again charging to a reasonable capacity.

For renewable energy, this energy storage system can bolster solar energy utilization by storing surplus power or sending out power, so that the grid power supply can be kept constant. In addition, it can also regulate solar power and reduce variation and fluctuations, allowing renewable energy to be connected to the grid stably.

Stabilizing the power supply for power plants during energy transformation

Whether it is traditional or renewable energy power generation, Delta’s energy storage system can play a critical auxiliary role, effectively providing silent support to the power grid by regulating at ordinary times and providing a backup power through dispatching in an emergency. Delta is the leading energy storage system supplier in Taiwan and can provide one-stop shopping services. This self-developed total solution has long been recognized by customers at home and abroad. For example, the Yongan Solar Power Plant in Kaohsiung and Ako Energy-saving Park in Japan both use Delta’s energy storage solutions.

For Taipower, Delta has successfully implemented an effective energy storage solution at the Kinmen Xiaxing Power Plant. After undergoing engineering, control, testing, and various challenges, the system was completed in 2020 through cooperation between Delta and Taipower R&D and engineering staff.

By providing complete products and services, Delta’s energy storage system met Taipower’s requirements for functionality, stability, and safety. In future, Delta will continue to invest in the development of systems with greater power and responsiveness, helping power plants stabilize their power supply during the energy transition.