Delta, drawing on its rich experience in electronics manufacturing, has developed DIAMOM, a smart manufacturing solution for the electronics assembly industry. DIAMOM integrates automation equipment, manufacturing execution systems, equipment networking, and visualization platforms to monitor production progress, WIP quality, efficiency, operations, and logistics in real time. Bridging IT and OT layers, DIAMOM digitizes the entire production process, visualized in a 3D war room, creating a cohesive and intelligent factory. Delta’s tailored consulting and design services ensure rapid, phased implementation, enabling efficient smart manufacturing for clients.

DIAMOM:Electronics Assembly Solution

Manufacturing Management Platform DIAWorks

Today’s manufacturing is characterized by stringent quality control, low-volume large-variety orders, and frequent changes. Automation is therefore critical for reducing line changeover and shortening production cycles. Delta has launched its comprehensive Manufacturing Management Platform DIAWorks. Leveraging its extensive experience in automation integration, Delta has refined the integration mechanisms of different system software. The DIAWorks Series software can be individually implemented or integrated to achieve a variety of synergies.

Automation Integration Platform DIAAuto

High-efficiency automation is a common goal for factories. However, most factories have difficulty integrating automation equipment and Manufacturing Execution Systems (MES). In response, Delta’s Automation Integration Platform DIAAuto offers a comprehensive equipment automation integration solution, which includes the DIAEAP+ Equipment Automation Program and the DIALink Edge Server Box. DIAAuto can convey the upper-level MES production plans and control commands to a variety of equipment, including production, inspection, storage, and transportation equipment. The equipment sends execution feedback results and inspection data to the MES. With OT and IT integration, Delta provides greater competitiveness for smart manufacturing.

Intra-Plant Logistics Platform DIATrans

Modern factories often face issues in warehouse and logistics management, such as inaccurate inventory, untimely restocking, low processing efficiency, and inefficient logistics operations. Delta’s DIATrans series addresses these problems by offering system integration and monitoring across production lines and warehouses. This includes raw material control, workshop logistics, finished product warehouse management, production process control, and automation equipment monitoring. DIATrans enhances production and transportation efficiency, reduces operational costs, and ensures smooth supply chain operations.

Industrial Communication Protocol DIAComm

Industrial Communication Protocol DIAComm enables equipment and upper-level system data integration in smart manufacturing. In IIoT, complex processes, language barriers between OT+IT layers, and highly customized but inefficient setups hinder integration. DIAComm offers standardized communication and control solutions for semiconductor and electronic assembly equipment with DIASECS and DIACFX. DIAComm provides equipment connectivity, data formats, and communication protocols, optimizing the connection of equipment and software systems. DIAComm accelerates the integration of heterogeneous systems and reduces maintenance challenges for equipment makers.

Digital Twin DIATwin

Digital transformation is a crucial step towards smart manufacturing. The DIATwin Virtual Machine Development Platform quickly constructs virtual machine 3D prototypes, accurately estimates equipment processing time, and verifies product specifications. DIATwin enables equipment program development and error troubleshooting in a virtual environment. The goal is to help businesses achieve cyber-physical integration and accelerate new product introductions.

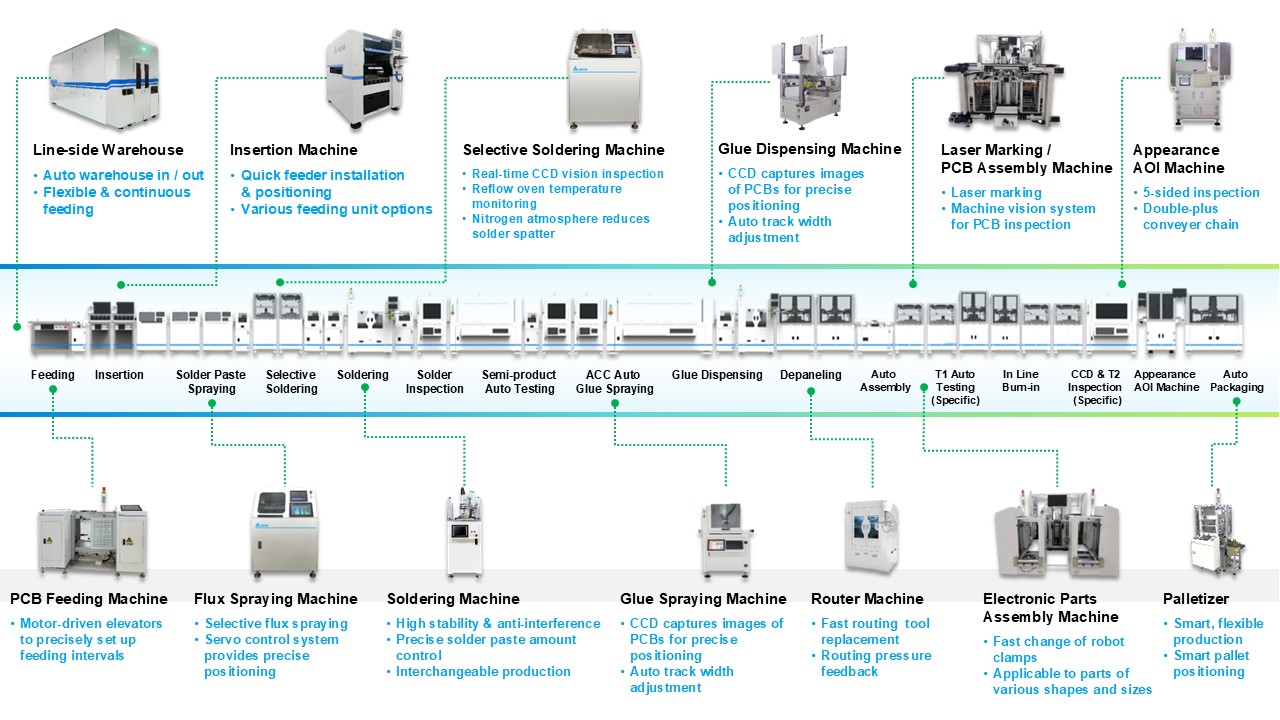

Smart Equipment

Delta smart equipment is widely used in three major industries: electronics assembly, semiconductors and passive components. With 30 years of experience in these fields, Delta has dedicated teams for mechanical design, electronic control design, inspection design, and AI design to develop standard and customized equipment for production line integration. Providing fast and flexible pre-assessment and localized after-sales services, we implement successful factory solutions in many countries. Delta also offers consulting services to upgrade smart production lines with highly efficient, precise, and reliable solutions.

In 2022, Universal Instruments joined Delta to provide its exclusive leading technologies for electronics assembly, advanced packaging, and precision automation solutions. Together, we can deliver a comprehensive product portfolio, especially for the semiconductor industry, and localized services to enhance our customers’ competitiveness in manufacturing capacity.

【 Electronics Assembly 】

【 Semiconductor 】

Automation and Integration of Smart Production Lines

In addition to equipment design and manufacturing, Delta provides tailored consulting and planning services for production line upgrades. Our services can be combined with Delta’s comprehensive product lines, such as control/networking components and automation equipment as well as systems for IoT, visualization and manufacturing management. We enable our customers to efficiently manage production status, quality of works in process, equipment efficiency, warehouse and logistics. By thoroughly integrating the OT and IT systems, we assist customers in gaining a competitive edge by setting up their intelligent factories step by step.

Smart & Green Facility Management Solutions

Delta’s SCADA (Supervisory Control And Data Acquisition) and industrial energy management solutions let you monitor and control your facilities at different levels. By clearly visualizing real-time data you can efficiently control your facilities while you scale your business.

Delta’s SCADA solutions, VTScada and DIAView, allow centralized monitoring of water, electricity, oil and gas status, and let you eliminate potential issues and adjust parameters in real time for smooth production. These solutions offer faster system response with in-time reaction to alarms for a more stable production environment, and capture system data for optimizing production processes.

Delta’s energy management system DIAEnergie is designed for precise monitoring of facility operation and energy consumption. The system powers assessment and planning of energy usage strategies. By analyzing the acquired data, companies can identify opportunities to improve equipment operation and electricity efficiency to enhance competitiveness and sustainable operations.

Factory Management and Control System (FMCS)

- Centralizes monitoring, automated tracking, and alarms, which increase management efficiency for a safe and smart factory

- Facilitates integrating Delta’s comprehensive industrial automation products for precise control, including water, electricity, gas, chemical, air conditioning and security systems

Holistic Energy Management

System Integration

- Assesses and implements energy savings for equipment and drive systems, including mobilizing Delta’s widely-trusted drive products

- Integrates energy-saving devices, system control, and networking

- Optimizes energy efficiency with smart group control of devices

Data Analysis

- Captures real-time data of high energy consumption equipment to keep track of the energy system’s operation and safety

- Identifies energy consumption anomalies and energy saving opportunities.

Strategic Consultancy

- Develops energy management strategies and improves production processes to enhance energy efficiency for customers

- Achieves ROI targets faster for energy saving projects

.jpg)