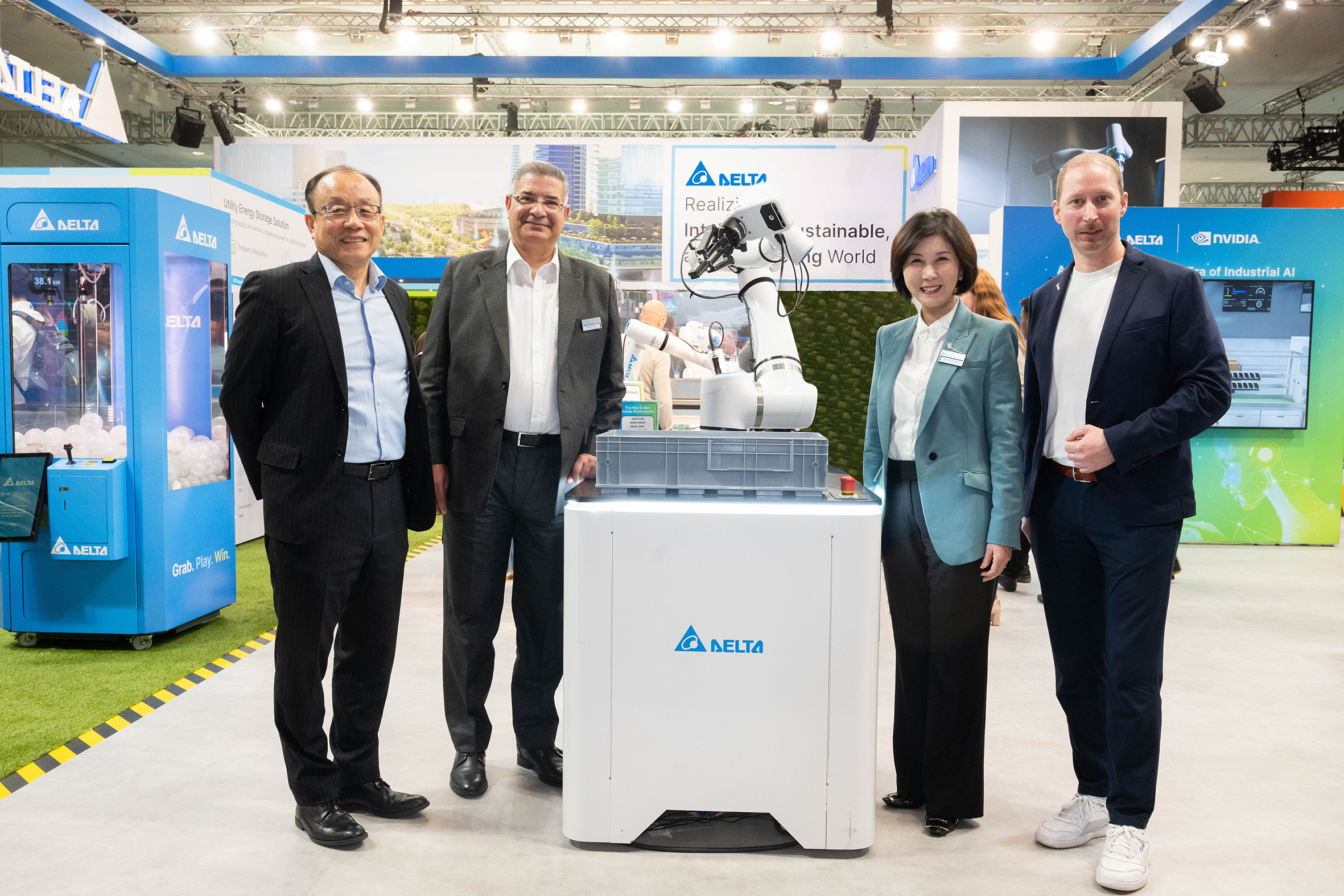

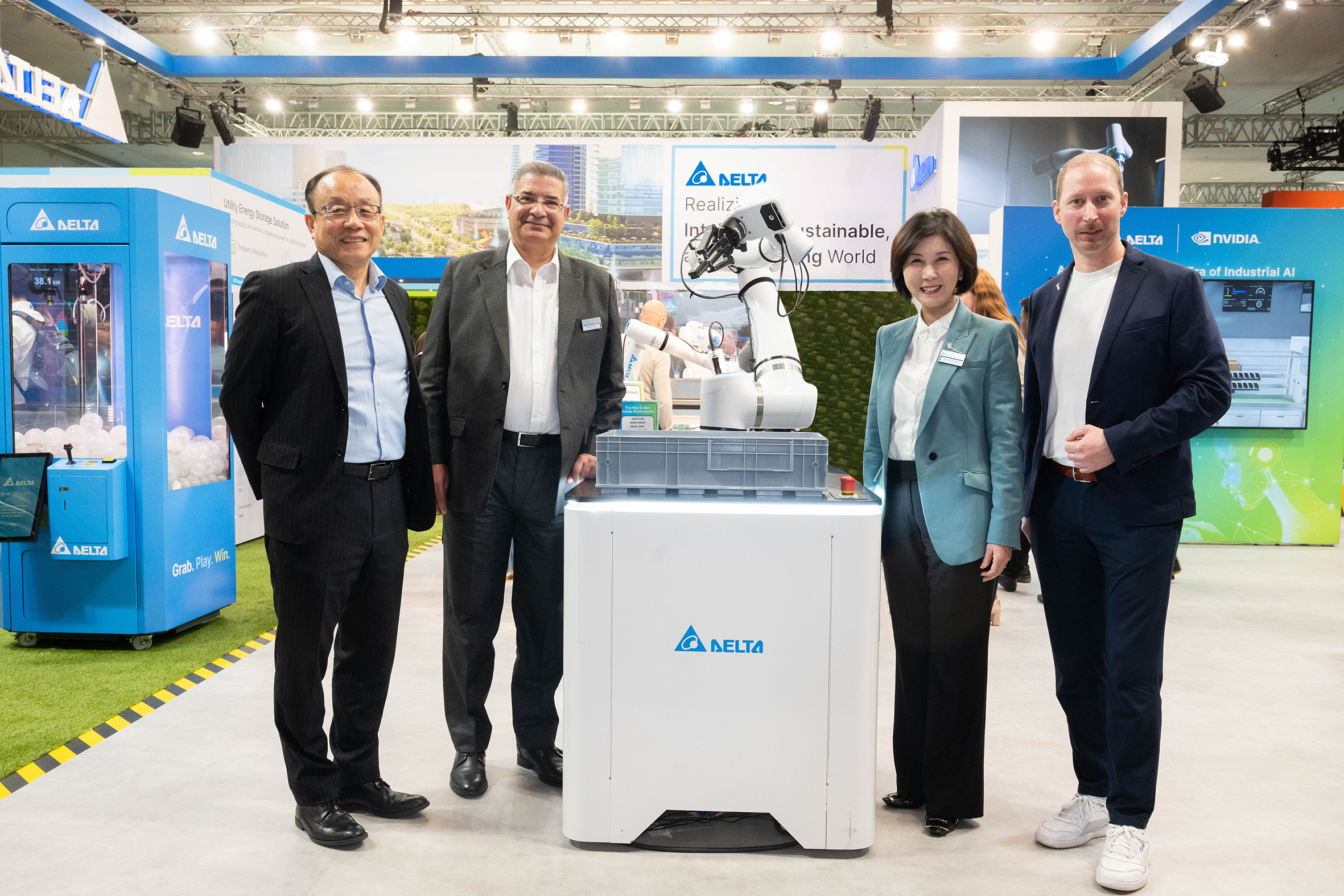

Ms. Shan-Shan Guo, Delta’s Chief Brand Officer (2nd from right); Mr. Dalip Sharma, Delta EMEA’s President & GM (2nd from left); Mr. Tim Lee, Delta EMEA’s Deputy Head (1st from left); and Michael Mayer-Rosa, Delta EMEA’s Senior Director for Industrial Automation (1st from right); introduced Delta’s cobot D-Bot series, equipped with the newly-launched Cognibot Kit, to media shareholders and customers during the press conference at Hannover Messe 2025.

Michael Mayer-Rosa, Senior Director, Industrial Automation Business Group at Delta Electronics EMEA Region highlighted that Delta’s R&D capacities, global presence and insights on vertical integration empowers a resilient and dynamic ecosystem.

The newly-launched Cognibot Kit for the D-Bot series cobots feature AI functions and intuitive human-machine collaboration. The system supports 360° speech recognition, 3D object detection, gesture control, acoustic feedback, multimodal AI interaction.

Delta leverages AI for real-time digital twin, enhances safety through predictive collision avoidance and optimizes performance with grip path training and AI model development.

Delta’s SIL3-certified Advanced IIoT Controller AX-5 and High-Performance Servo System ASDA-A3-EP ensure operational safety while delivering exceptional performance and connectivity.

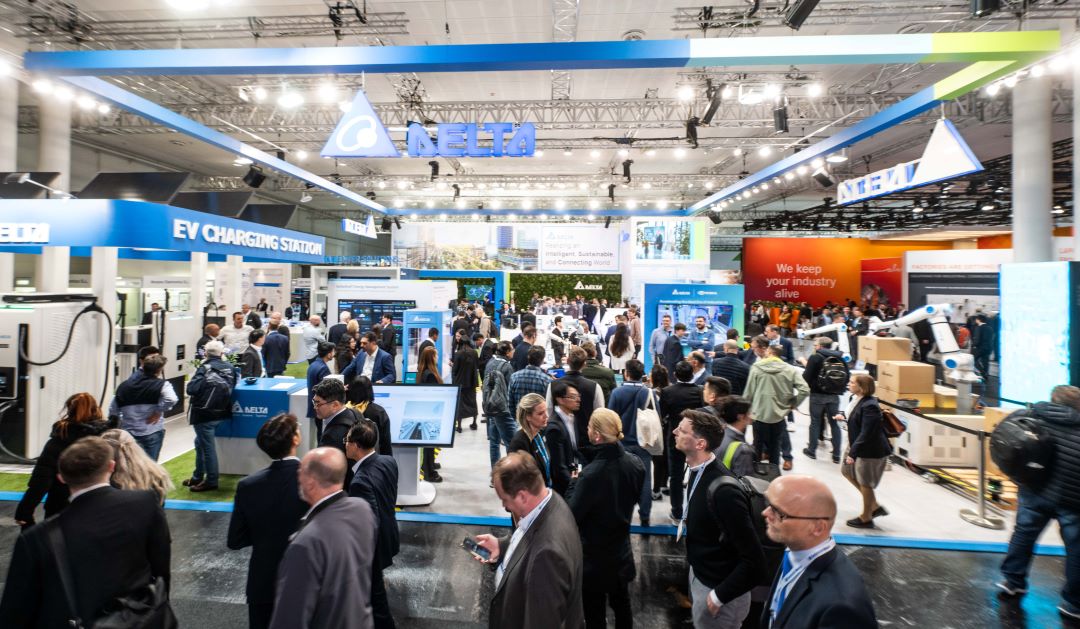

Delta’s smart and green solutions attract high attention from guests around the globe, making if one of the most popular booths during the Exhibition.

For the first time, Delta holds an evening social event on the second day of exhibition for global partners and customers to enhance interactions and partnerships.