Dr. David Tsai, the deputy head of Delta of Delta IABG, greeted the audience in Taoyuan.

Alisa Liu, the Motor Drive Solution product manager, explained the features of the Compact Multi-Drive MX300 for the attendees in Taoyuan.

Stanley Chiu, the Factory Automation Solution senior engineer, introduced the Virtual Machine Development Platform DIATwin to a full house at the seminar in Taichung.

The attendees in Tainan experienced the functions of the Smart Screwdriving System under the guidance of Ken He, the Industrial Motion Solution senior engineer.

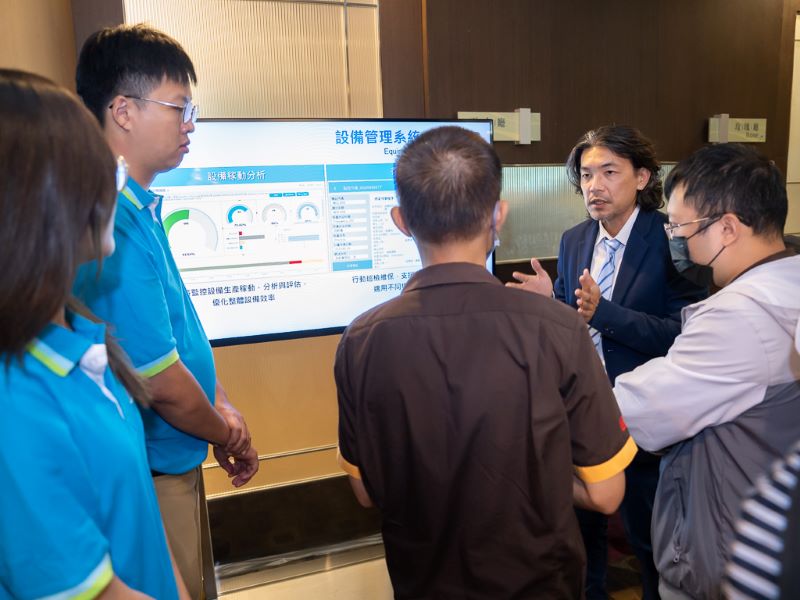

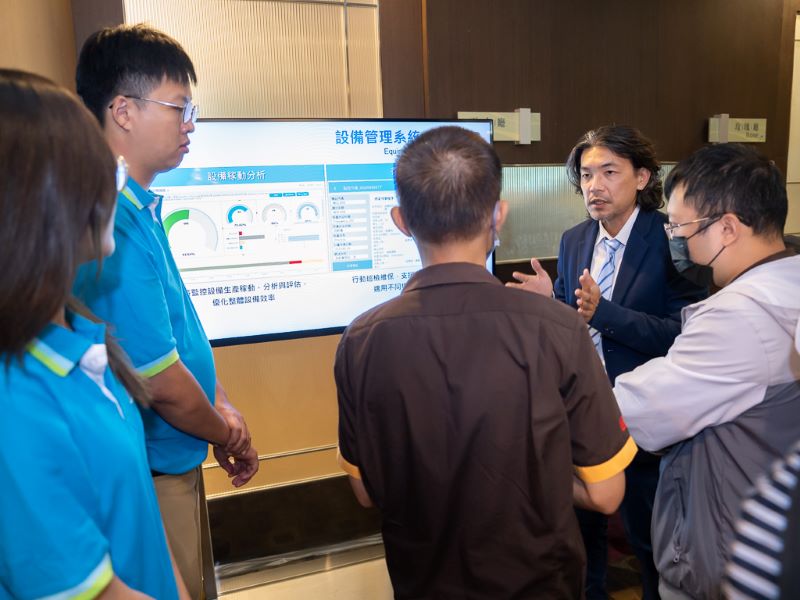

Yuren Chen, the Intelligent Solution Platform assistant manager, presented the features of Delta’s integrated smart manufacturing solutions for the attendees in Tainan.