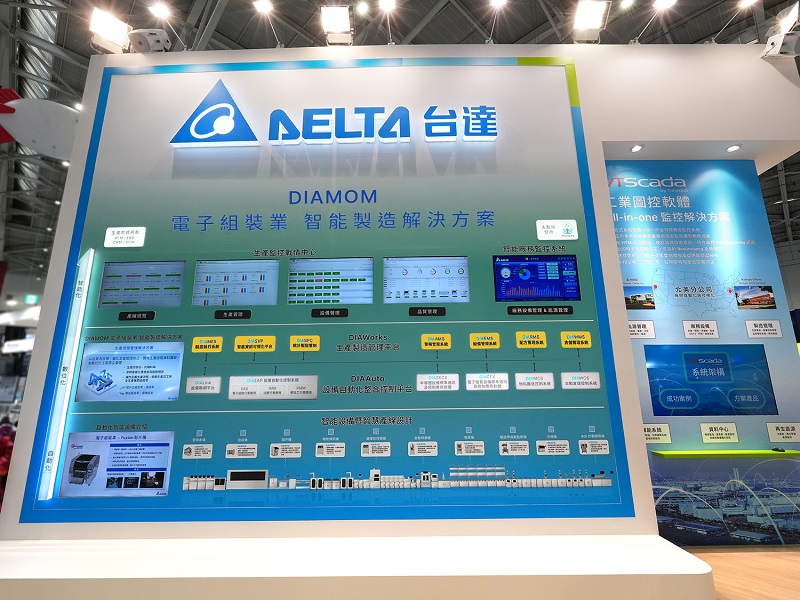

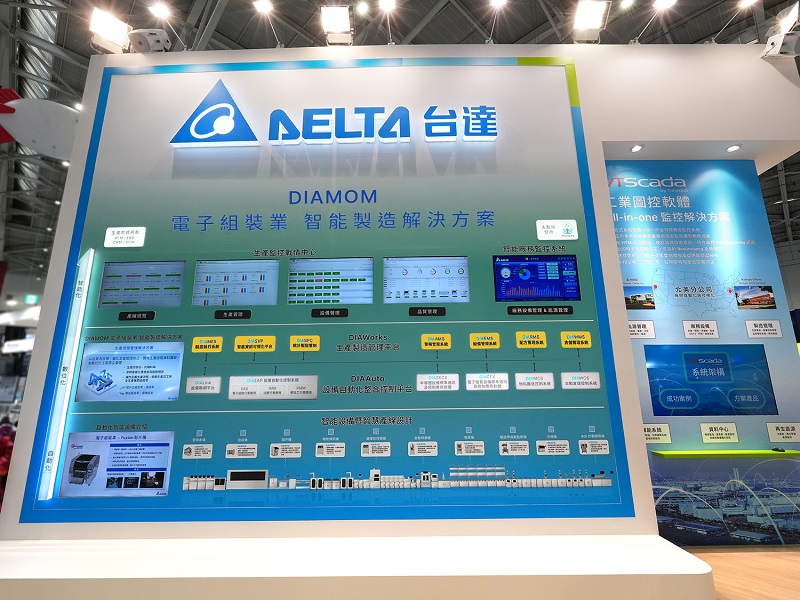

Smart Manufacturing Solutions for the Electronics Assembly Industry DIAMOM

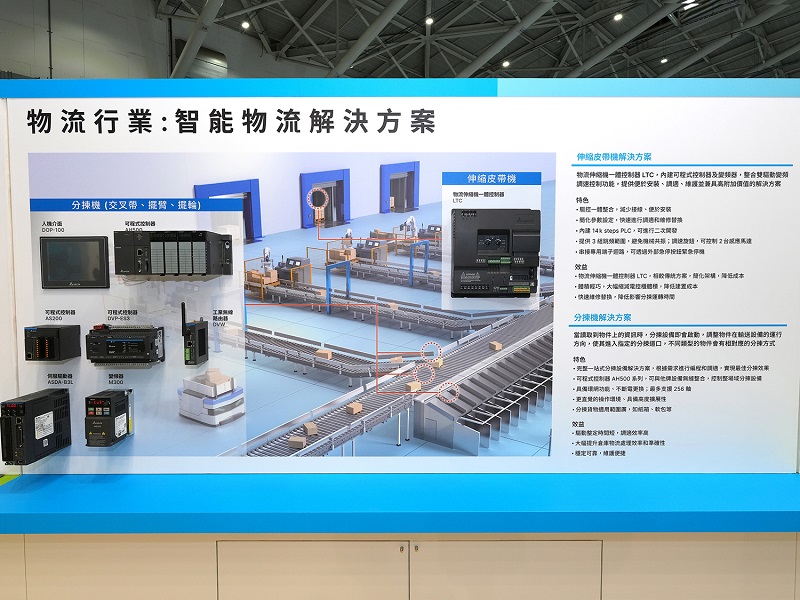

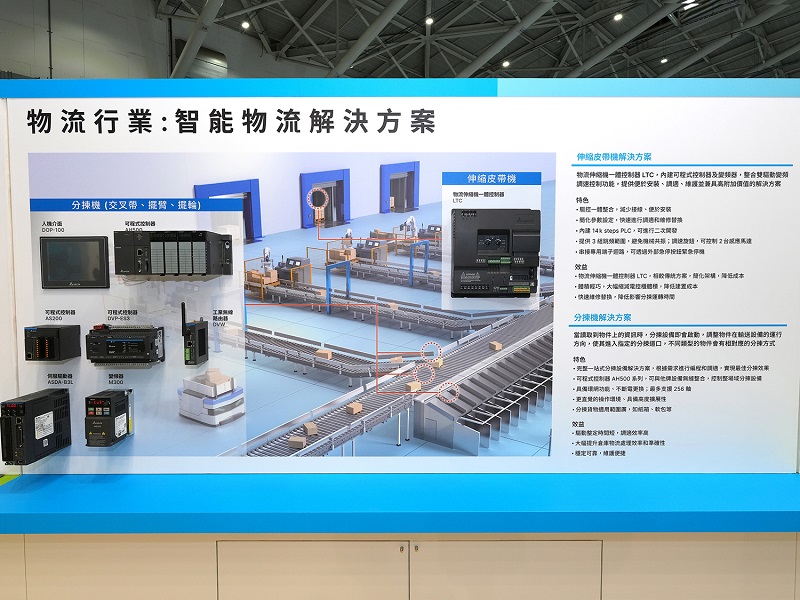

Smart Logistics Solutions

Virtual Machine Development Platform DIATwin

Digital Twin Machine Platform RTM/iRTM

SCADA System VTScada

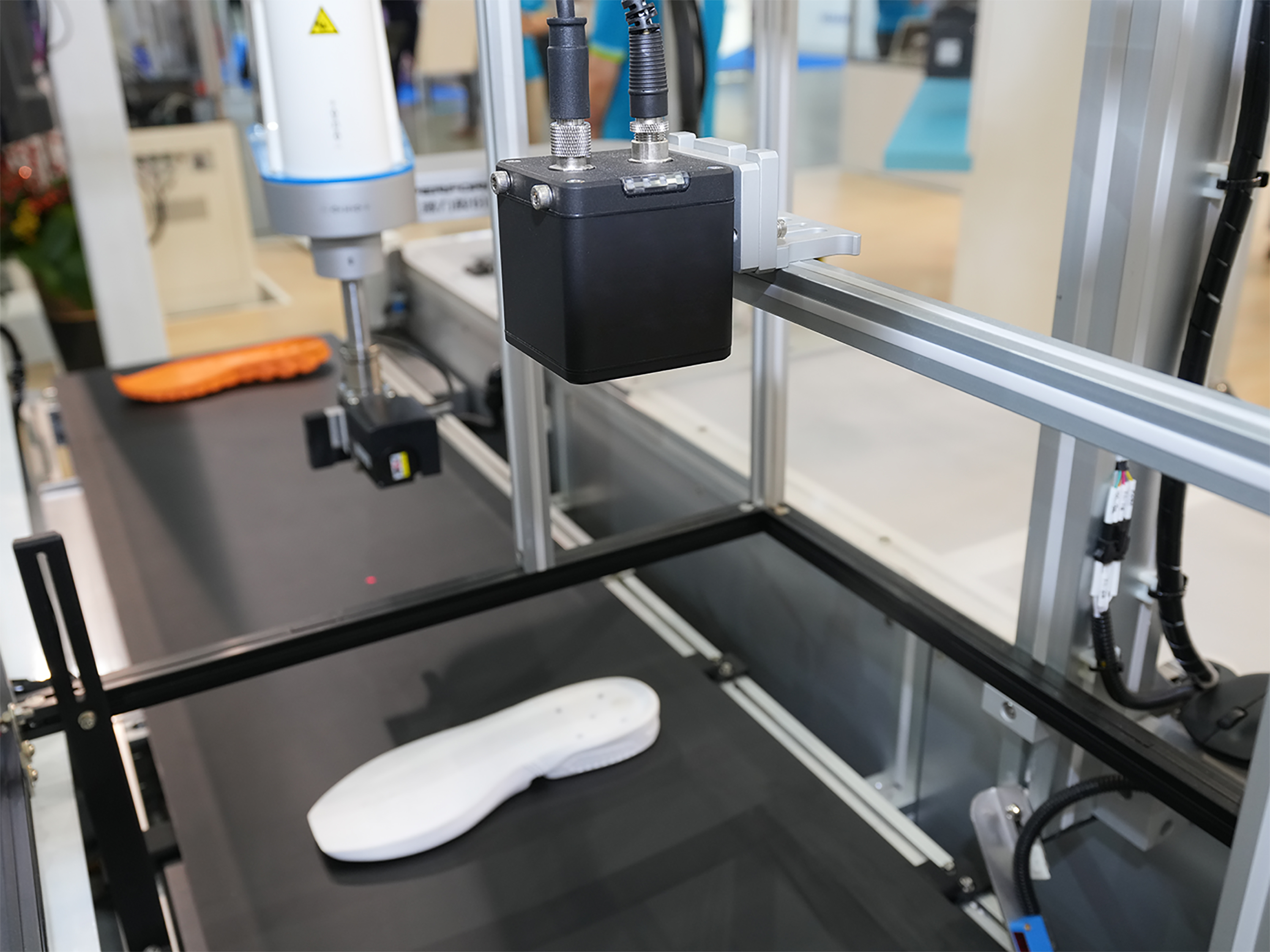

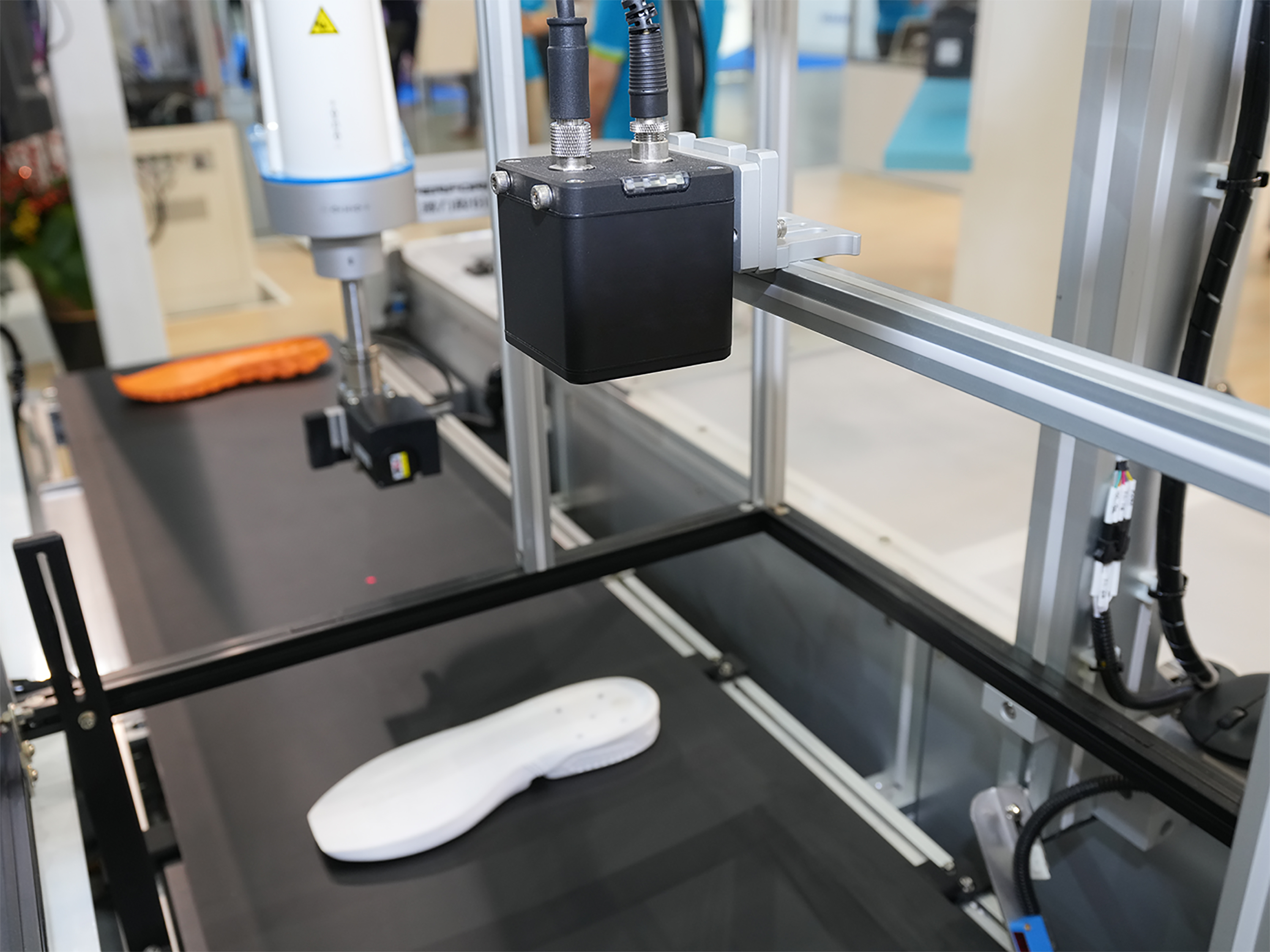

3D ToF Smart Camera DMV-T

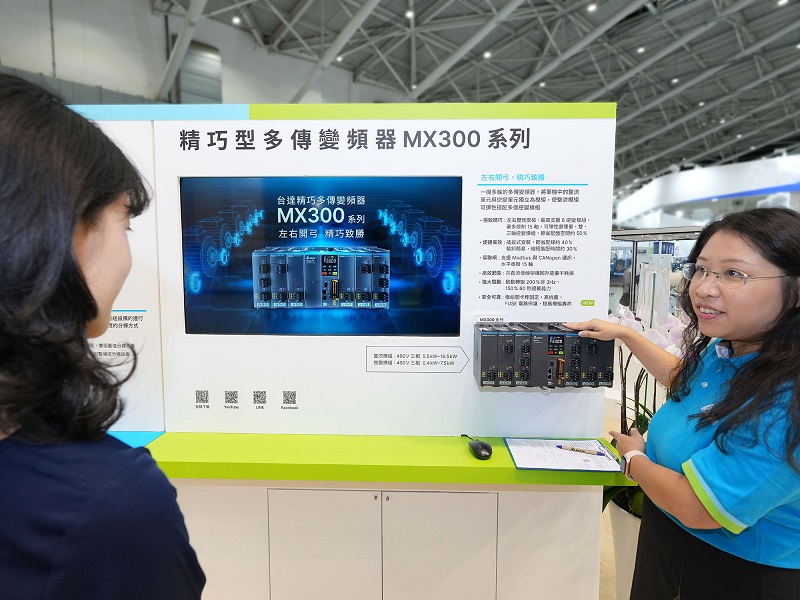

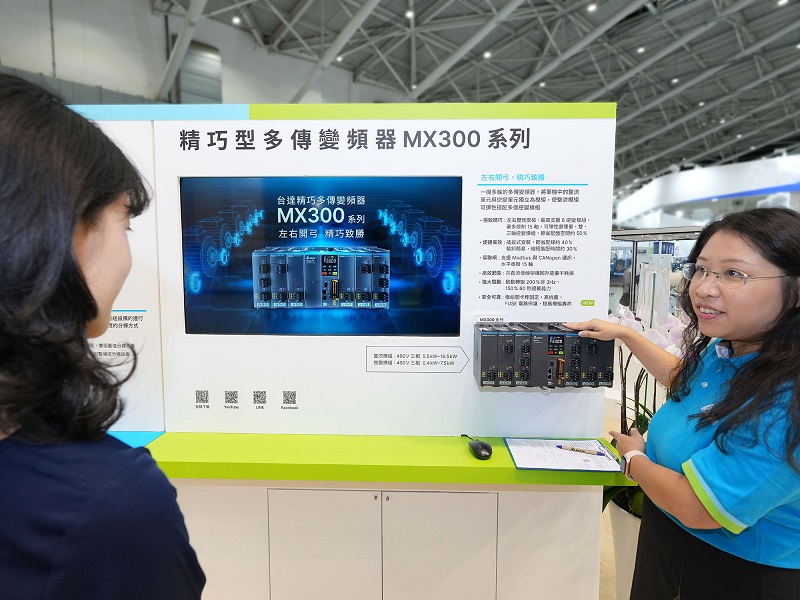

Compact Multi-Drive MX300