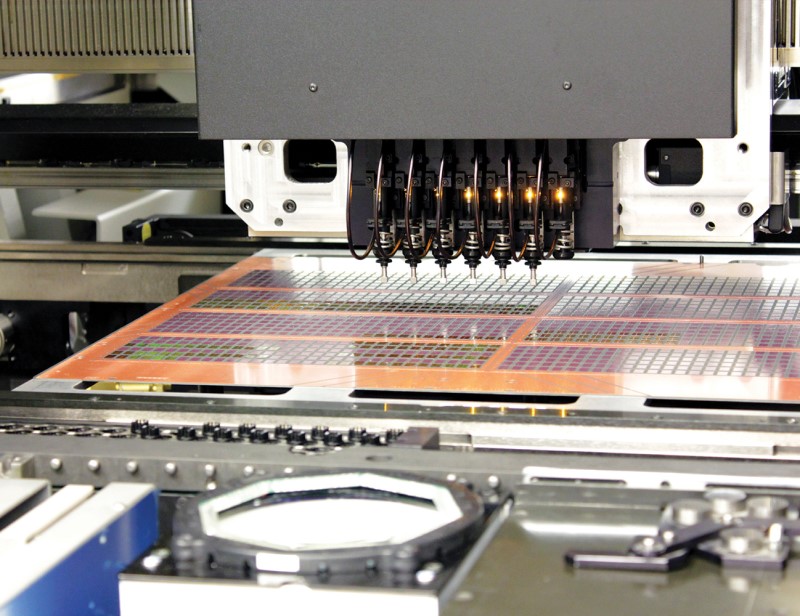

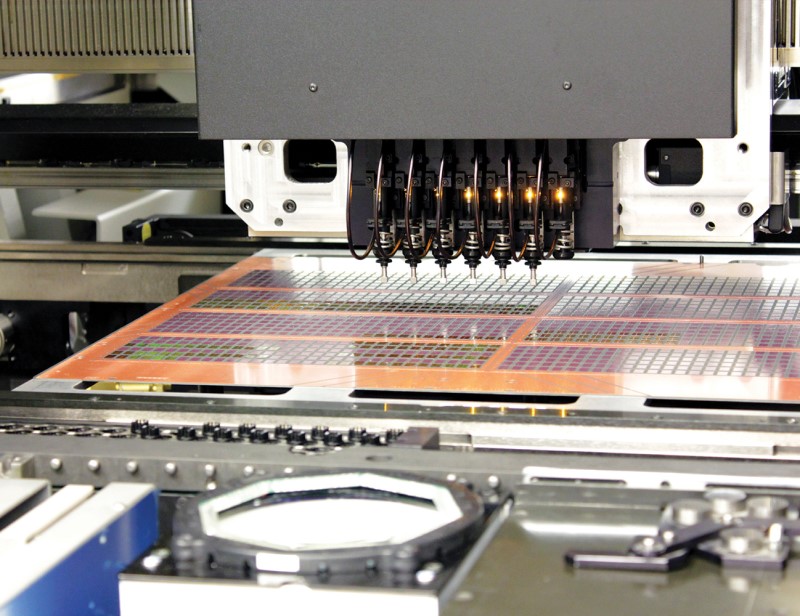

Universal Instruments has become the newest member of the Delta family. Offering potential synergies with sister business units, Universal Instruments will be a new growth engine for the Delta IABG to tackle the precision automation field with collective product and service offerings.

Universal Instruments is committed to creating pioneering solutions for all aspects of electronics assembly and to maximizing customers’ return on investment across the entire product lifecycle. As a new member of Delta’s IABG, Universal Instruments looks forward to building a smarter future for the electronics industry together with the Delta team.