Mr. Chientan Lien, the CTO of Delta IABG, was impressed by the outstanding performances and creative thinking of the participants, which merged theoretical knowledge with practical applications under the theme of energy-saving.

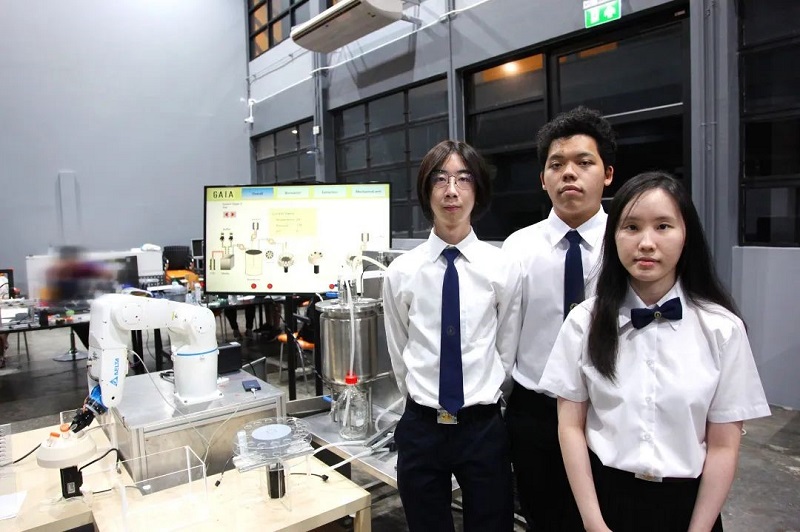

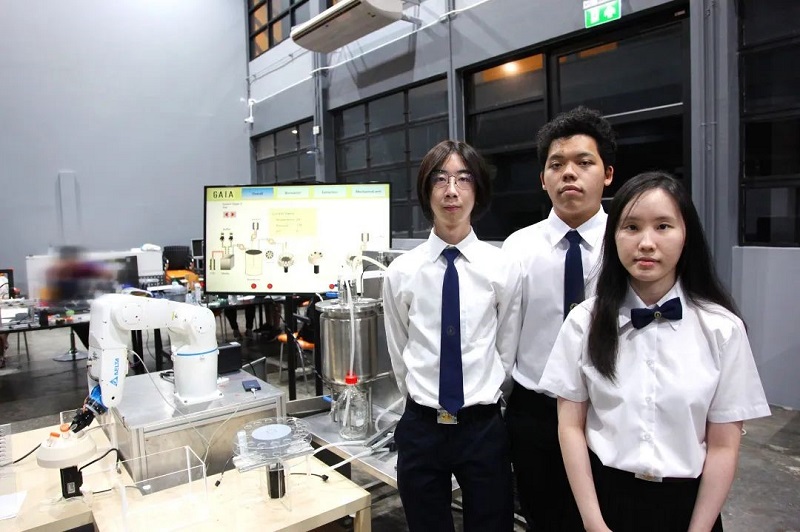

Team Gaia from Mahidol University (Thailand), presenting its “Carbon Polymerizing System”, was awarded Grand Prize in the 8th Delta Cup Contest.

Team Dream from Lanzhou University of Technology (China) introduced its “Dual Carbon Pioneer – A Multi-mode Interconnected Color-tunable Energy-saving Street Light Based on Composite Positioning”, took Grand Prize in the 8th Delta Cup Contest.