A plastic molding machine, also known as a plastic forming machine, plays an important role in the food, electronics, printing, and packaging industry manufacturing common plastics and blister packs for supporting ingredients, fruit, and electronic devices.

The Plastic Molding Machine Solution adopts Delta’s high-performance industrial automation products Compact Modular Mid-range PLC AS200 and AC Servo Drive & Motor ASDA-A2 Series. This core system enables the high-speed response function to substantially boost the equipment efficiency and simultaneously reduce energy consumption.

The EtherCAT/CANopen protocol transmits the production information to the Modular Mid-range PLC AS200 and Advanced Ethernet HMI DOP-100. With the support of the Industrial 4G Cloud Router DX-2100L1B, it solves the problems of manual operation by remote control and the adjustment in the production parameters.

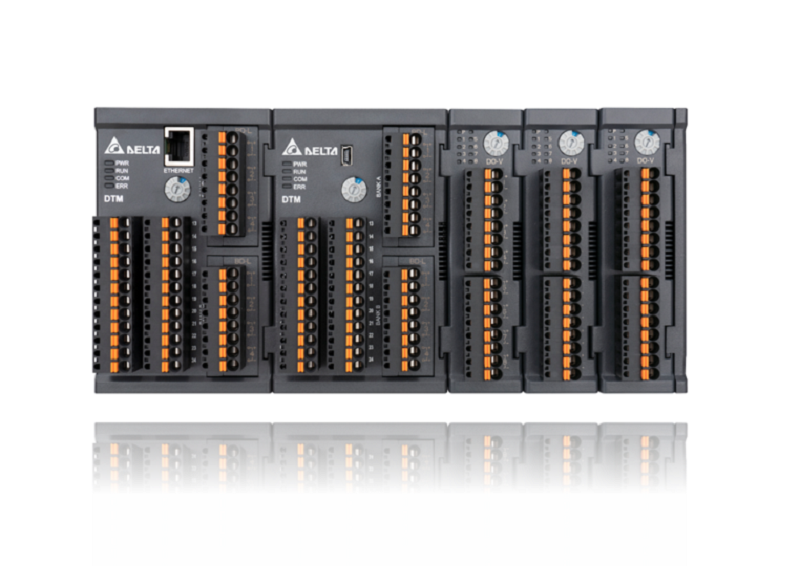

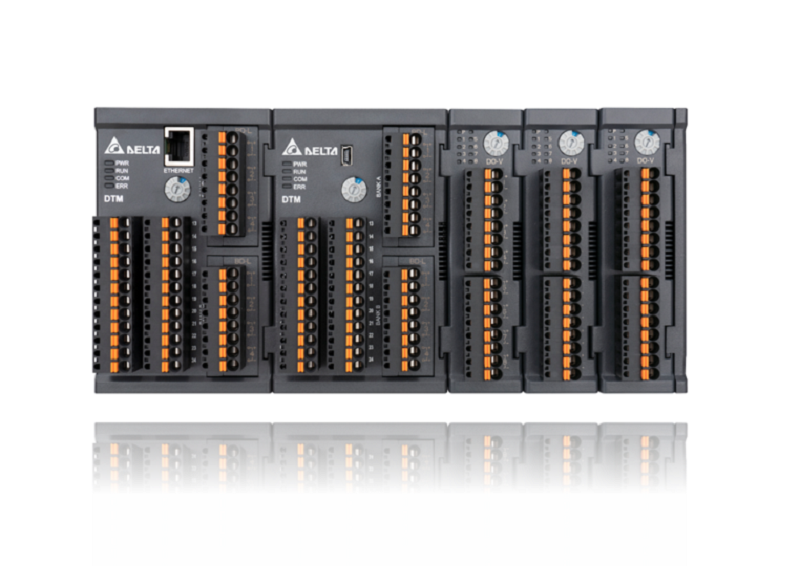

In the plasticizing process, the Multi-Loop Modular Temperature Controller DTM Series controls the heating status and receives real-time data for precise temperature control to enhance product quality.