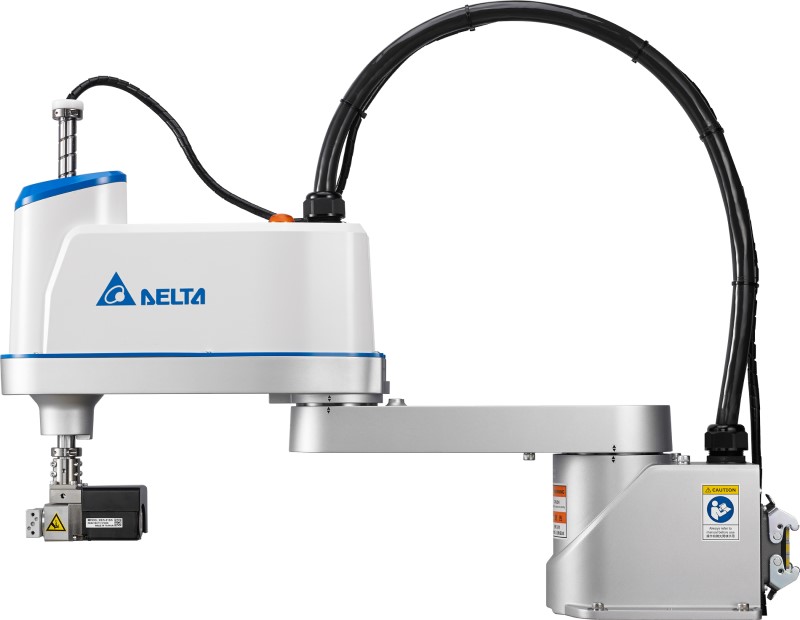

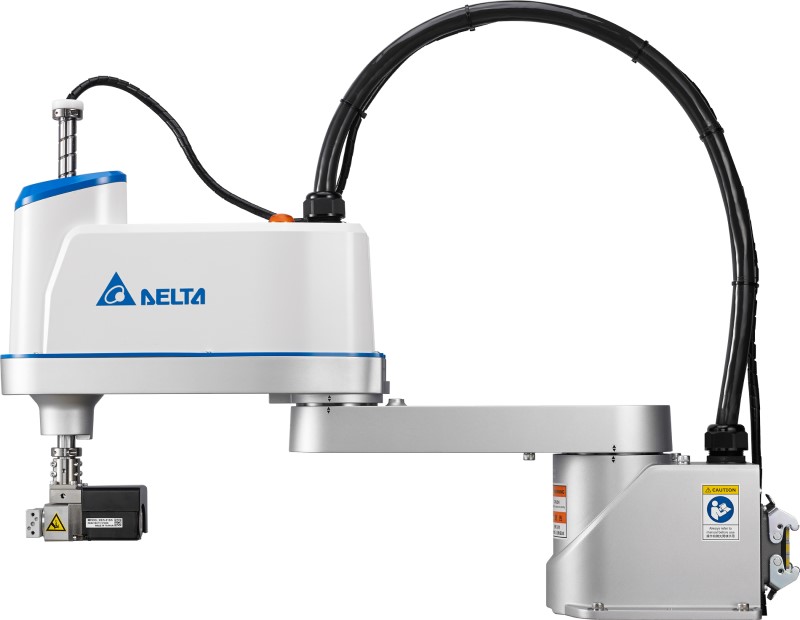

Delta’s SCARA Robot with integrated 5th axis won the Silver Award – Motion Control Category at the 2021 LEAP Innovation Awards. The solution integrates Delta’s patented 5th axis extended module with the standard SCARA Robot DRS60L Series to lower the threshold for industrial robot implementation.