Delta showcased its comprehensive electronics assembly and semiconductor advanced packaging solutions at Productronica in Munich from November 18 to 21. The EPIQx Platform for high-precision SMT made its global debut.

At the EPIQx global launch event on November 18, Delta highlighted glocalized smart manufacturing strategies to tackle the explosive growth in semiconductors and challenges of tariffs, labor shortages, and manufacturing site decentralization.

The Uflex® Platform allows fast changeover between odd-form insertion, SMT placement, dispensing, and screwdriving. Supporting components up to 440g, it is perfect for complex assembly processes across the automotive electronics, AI server, aerospace, and defense industries.

The Virtual Machine Development Platform DIATwin integrates with the High-Speed Smart Insertion Machine to auto-generate optimal paths and feeder assignments, followed by virtual validation, to enhance layout efficiency and accuracy.

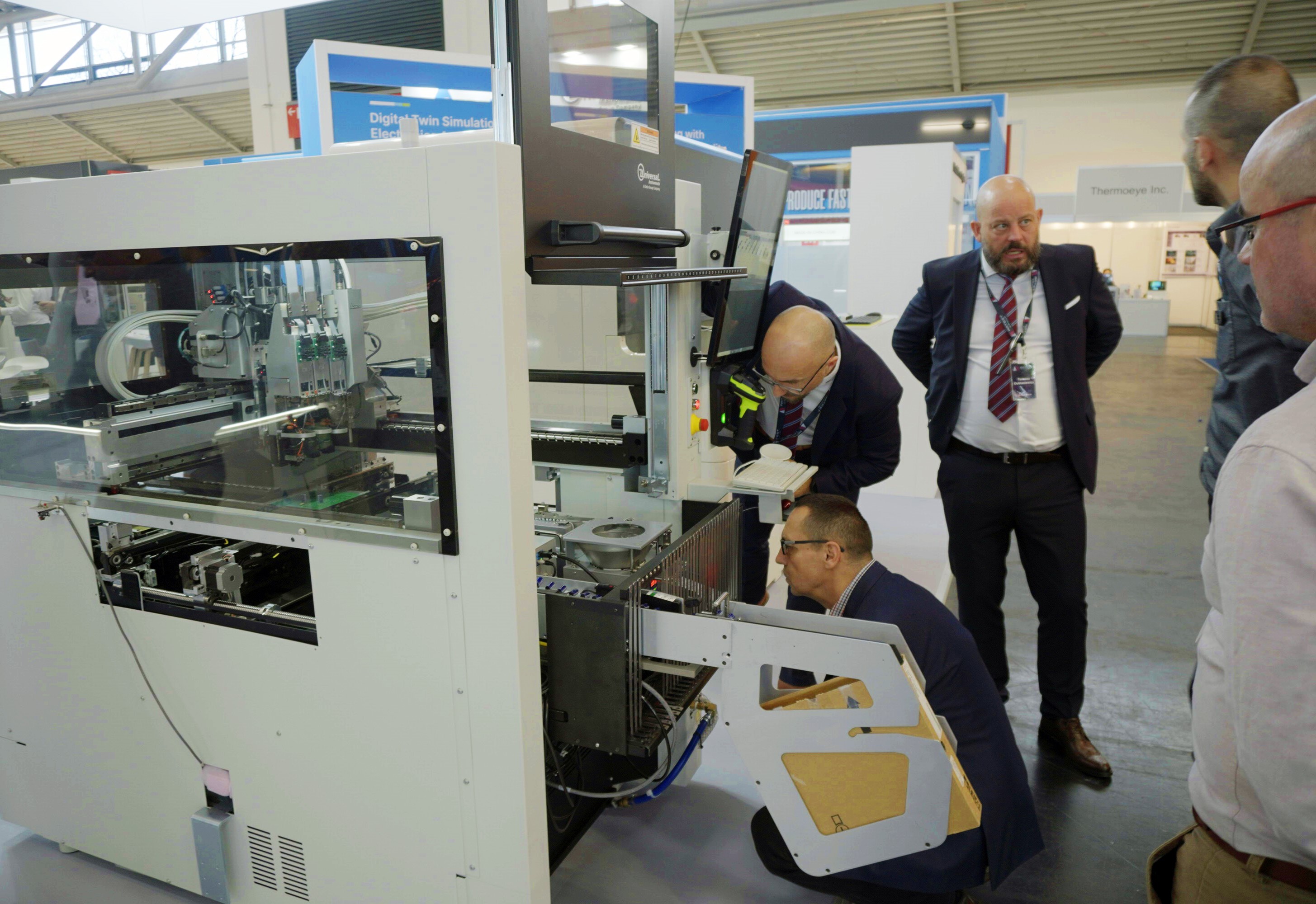

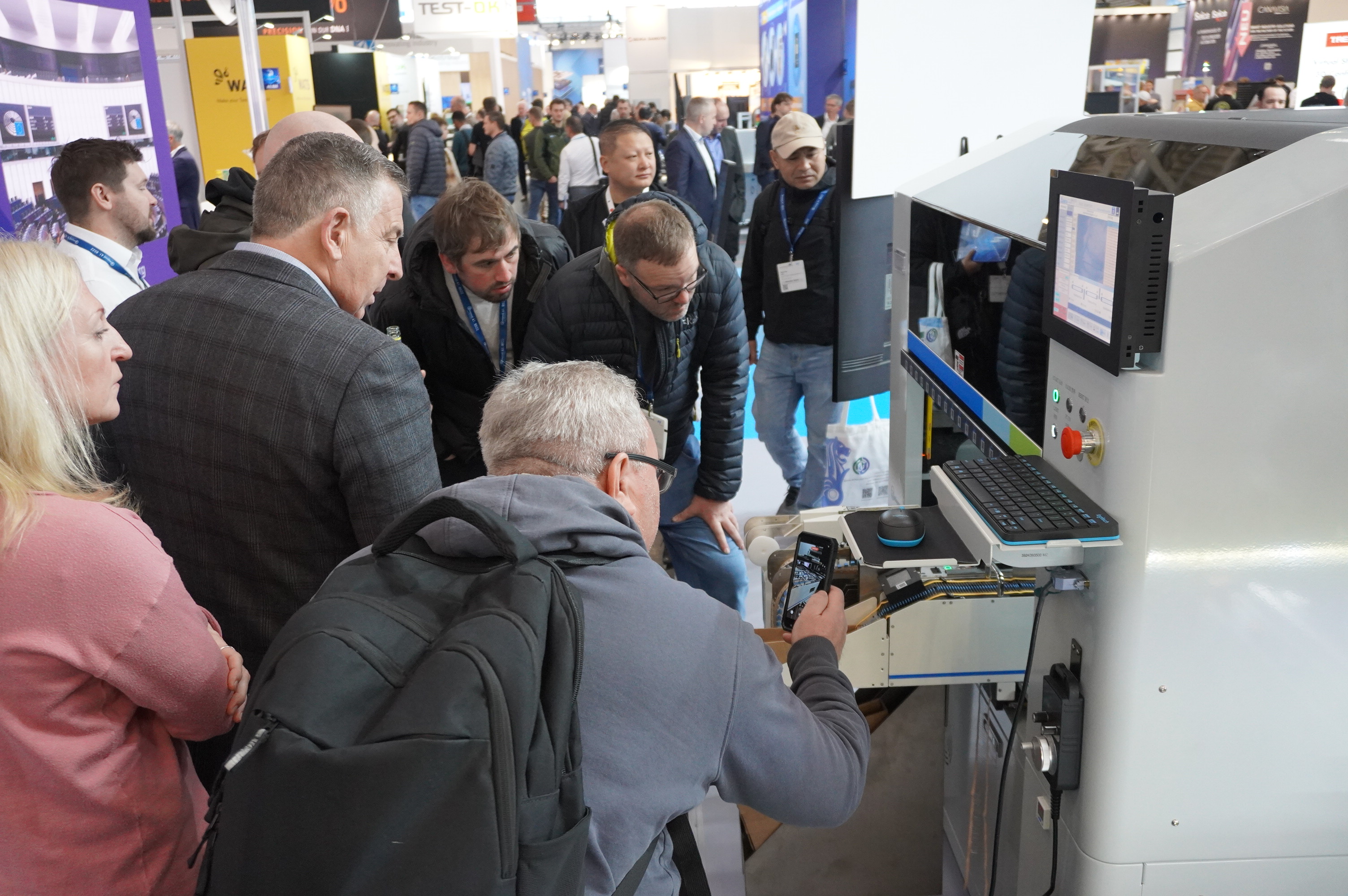

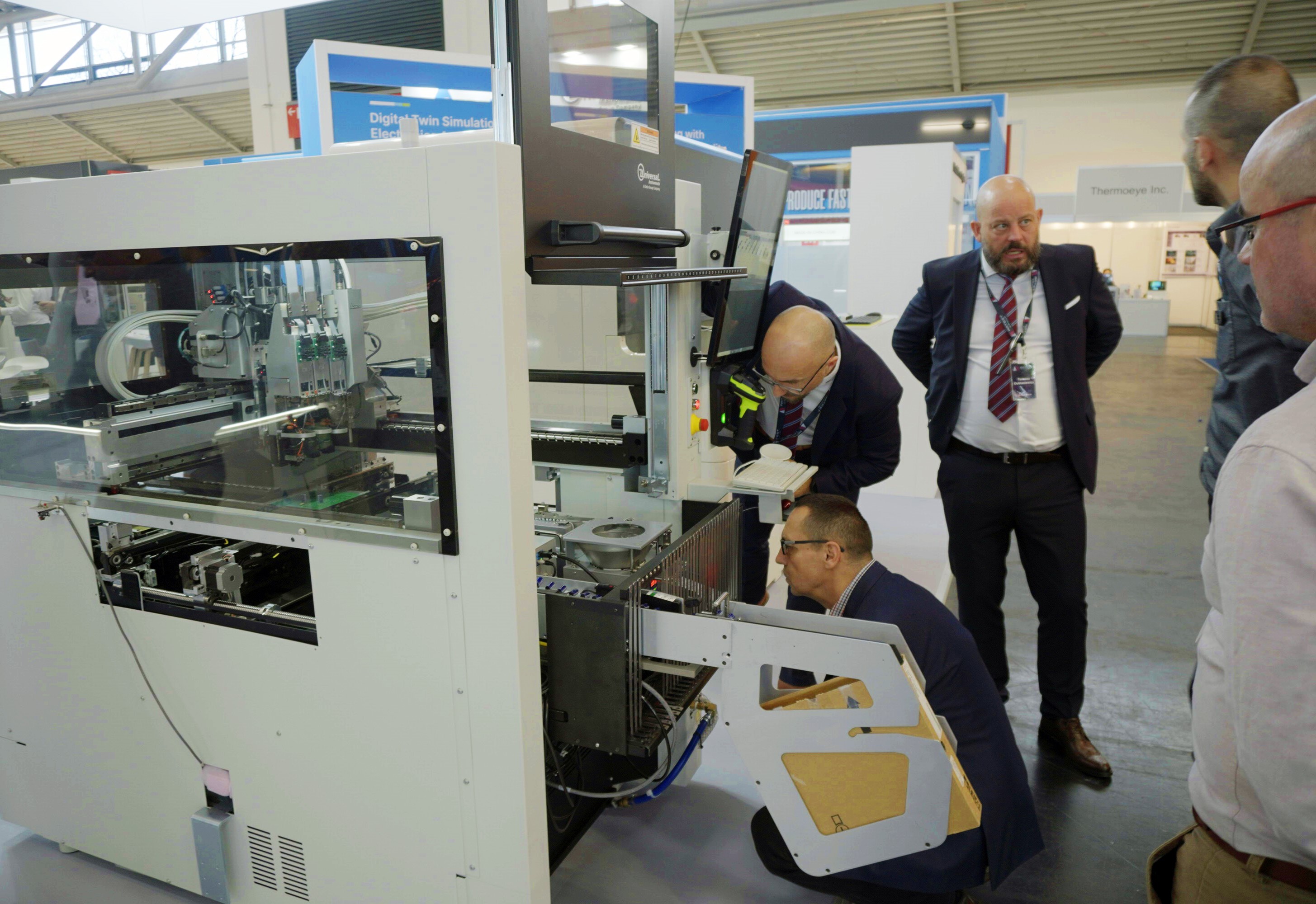

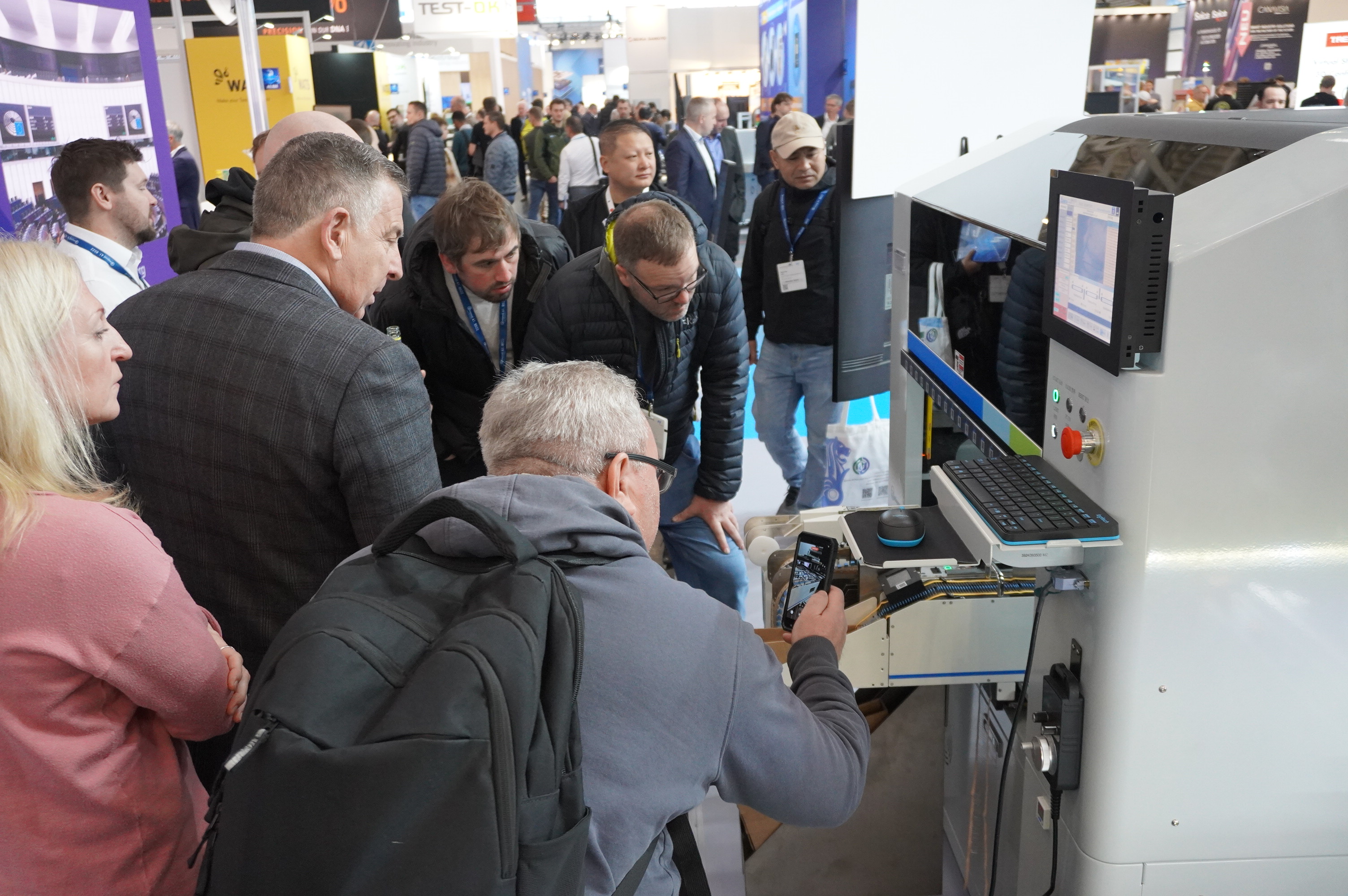

Delta attracted attention with its comprehensive electronics assembly product portfolio, which covers from bottom router, inserter & press fit, to high-precision SMT placement. Image: High-Speed Smart Inserter D30.