F.N. Huang, vice president of PSI, and Midas Chang, senior director of information systems, share the automation journey of the company’s Chung-Kang Branch at Taichung Port Technology Industrial Park.

With Delta’s DIAMES and PSI’s EAP and OHT fully integrated, the automation solution has skyrocketed efficiency.

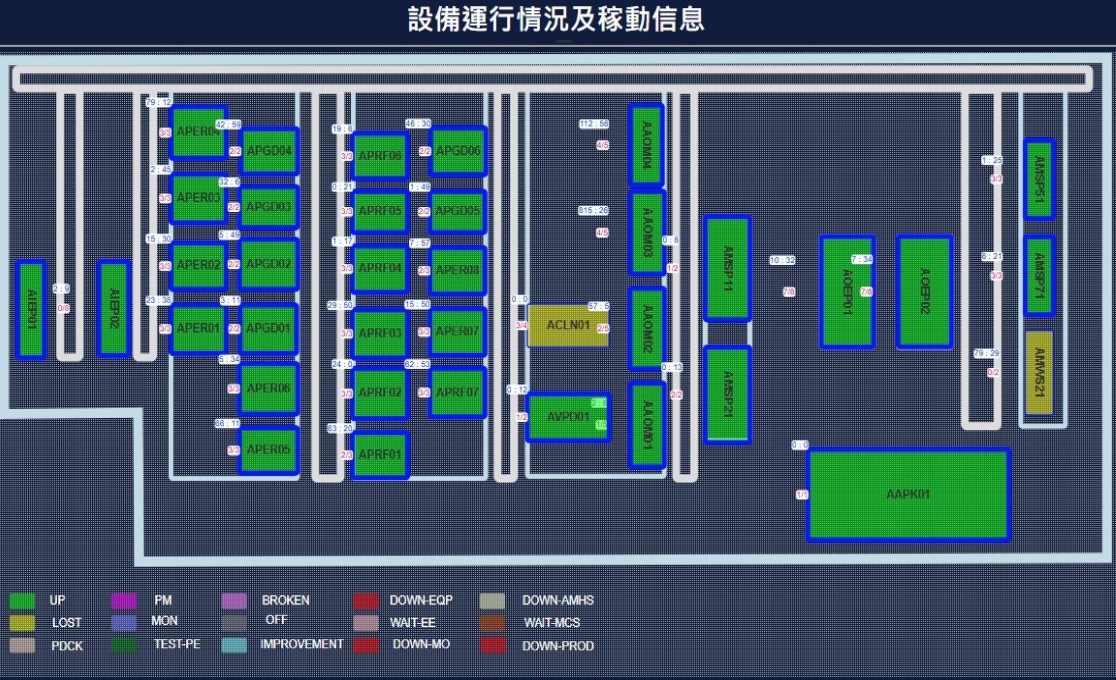

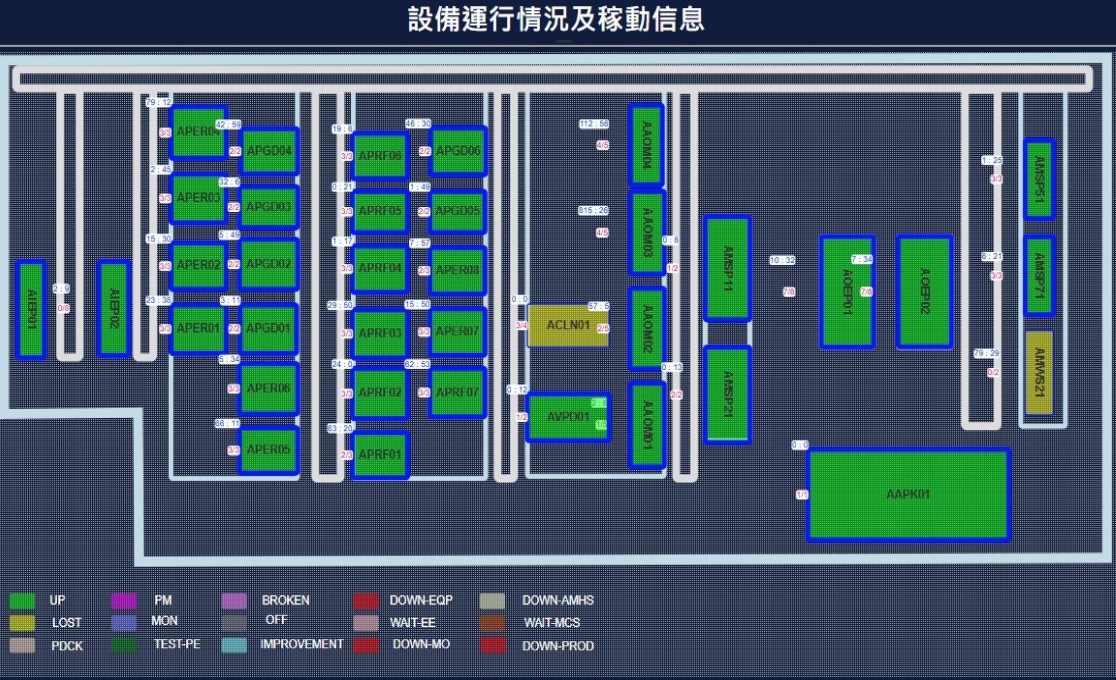

Delta’s DIASVP Smart Visualization Platform provides key production line information, enabling factory managers to monitor and control remotely in real time.