Delta unveiled multiple smart manufacturing innovations at the 2024 SPS Nuremberg expo.

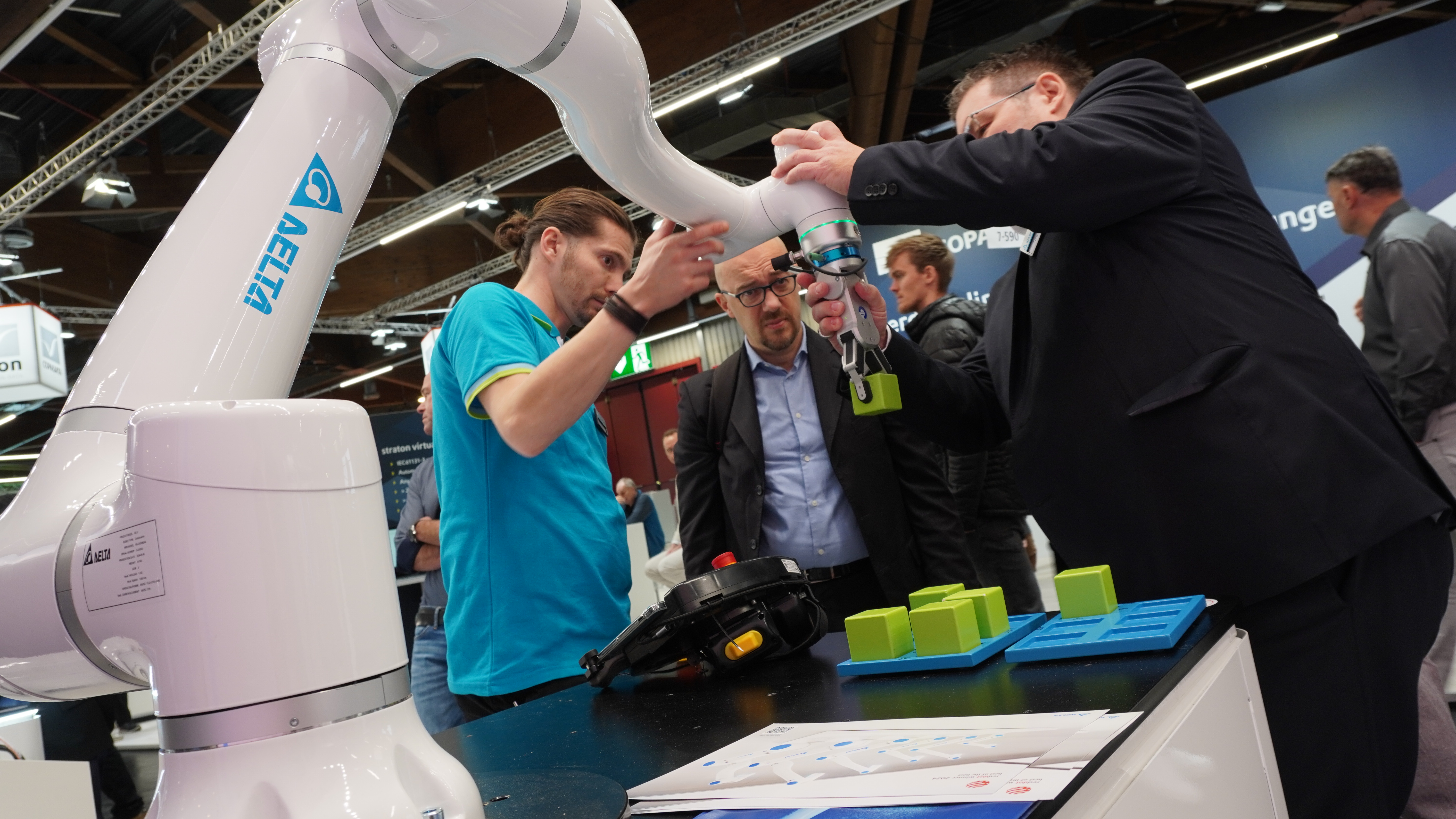

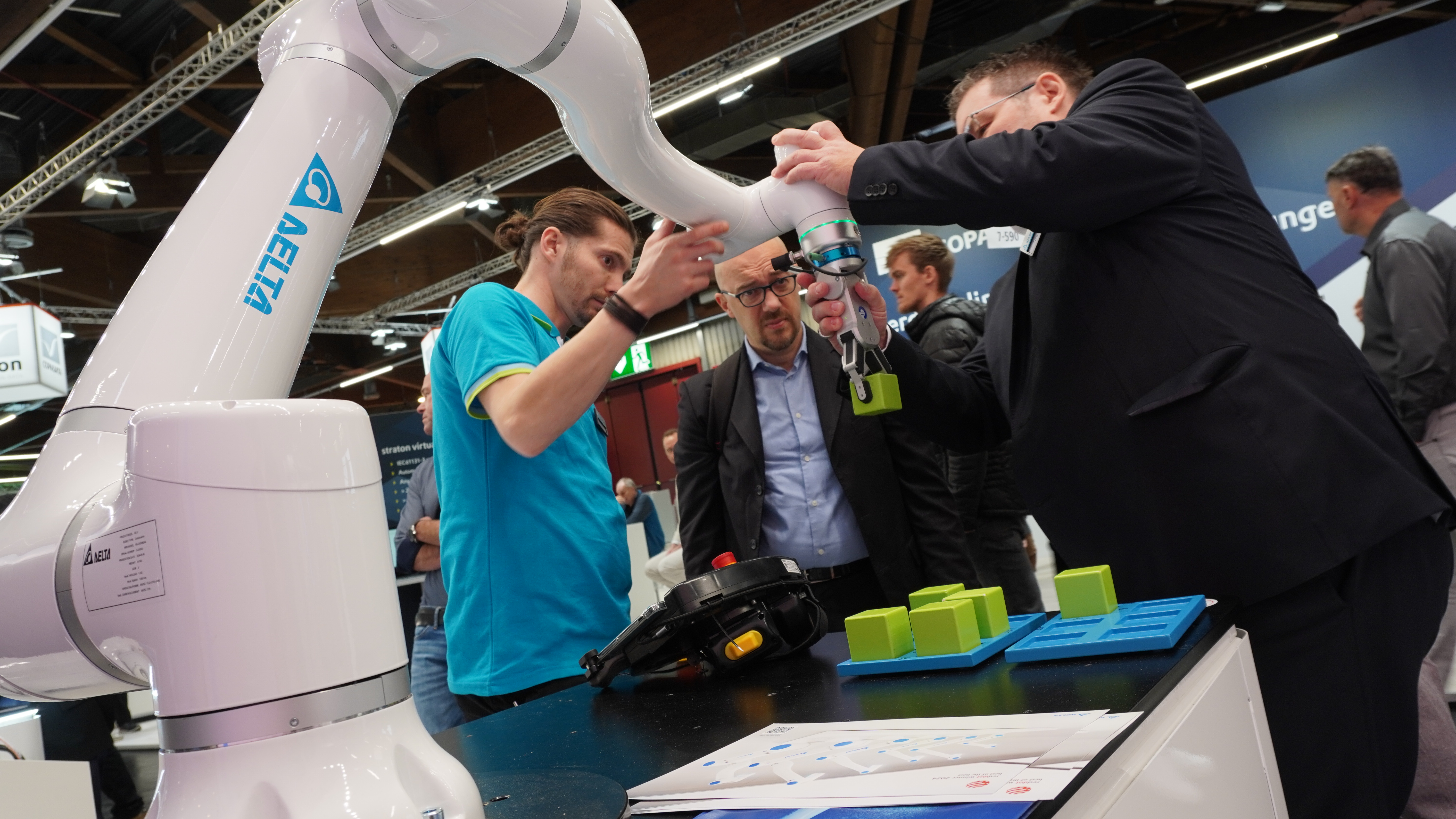

D-Bot Series Cobots upgrade factory automation with seamless human-machine collaboration, high precision & flexibility, as well as advanced safety functions.

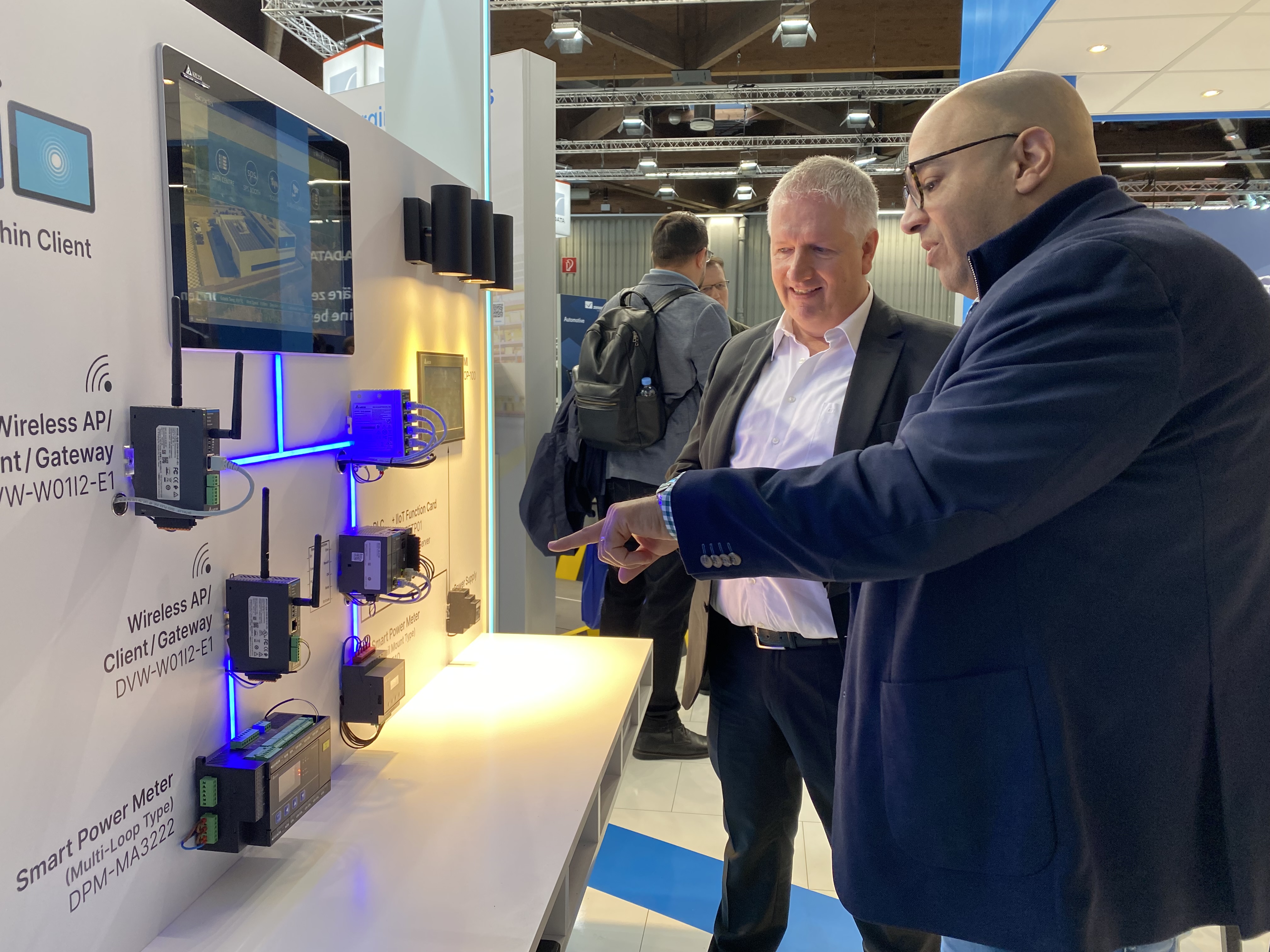

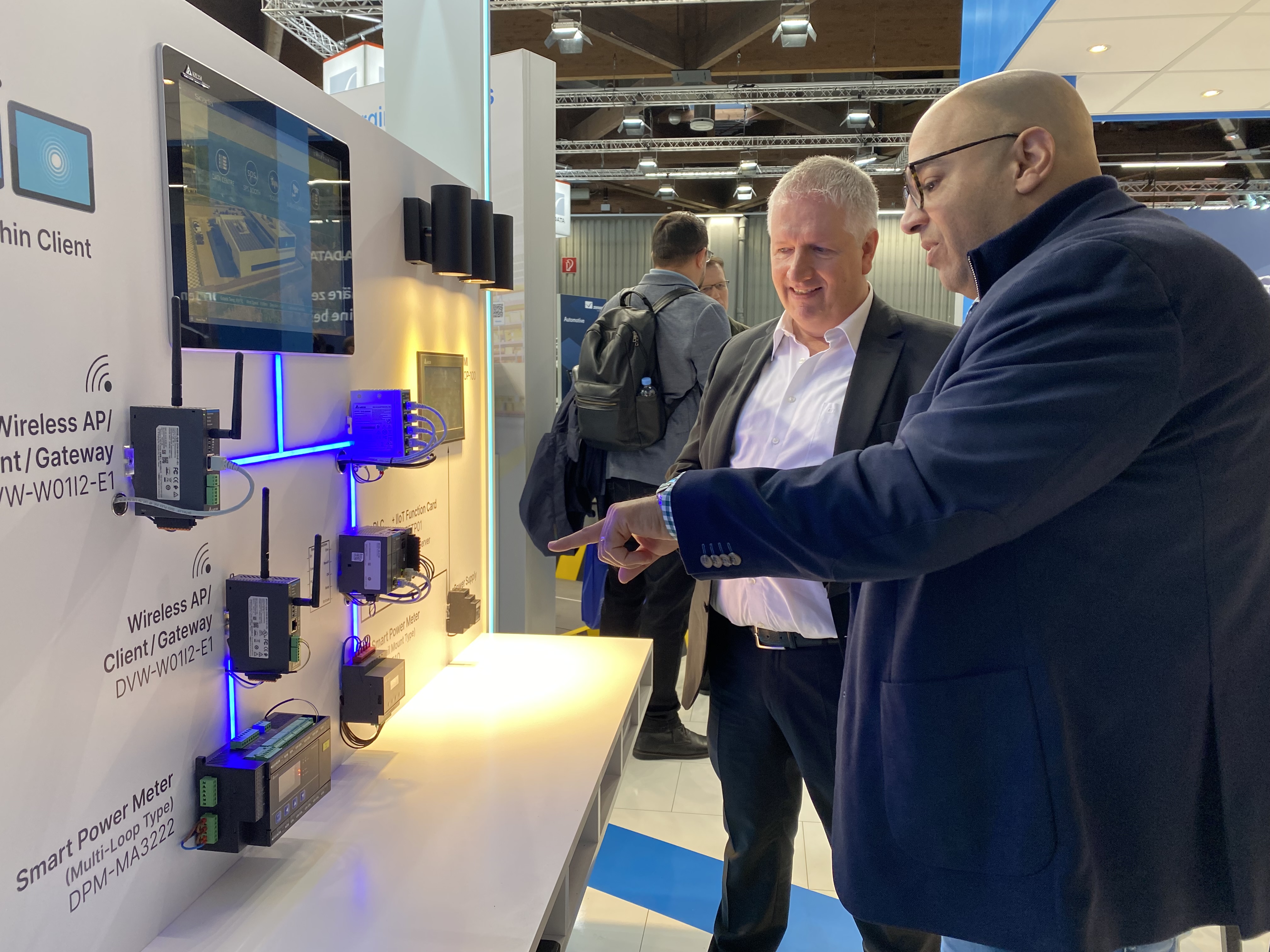

The AX-5 Series Advanced IIoT Controller, honored with the Taiwan Excellence Award, empowers equipment makers to cut costs and speed up development.

SCADA System VTScada offers remote real-time monitoring.

Open-Loop Variable Torque Standard Drive VP3000 Series is designed for the fluid industry, providing exceptional performance.

Delta's 6-Axis Articulated Robot is suitable for electronics assembly, metal processing, and rubber/plastic industries.