Delta DIASECS-GEM Software Solution includes a Library that supports the GEM 300 standard. The Library automatically processes the message into the GEM standard, with no need to understand the designated message format.

Ta Liang Technology, a semiconductor equipment manufactuer headquartered in Taoyuan, Taiwan, primarily develops and sells metrology, AOI, and automation equipment.

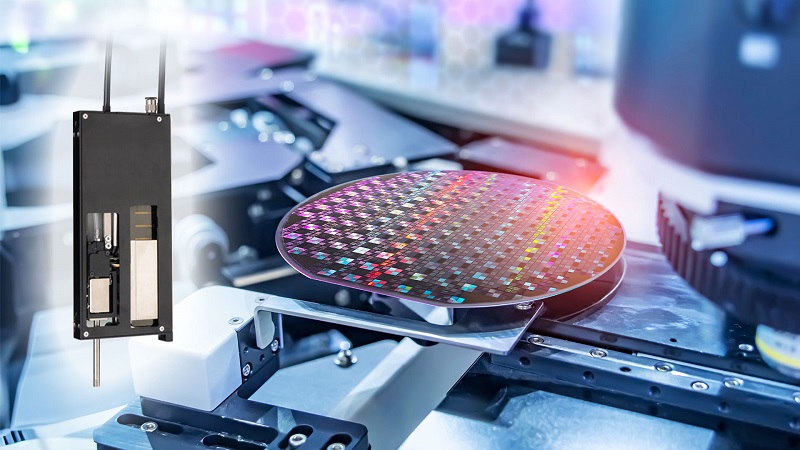

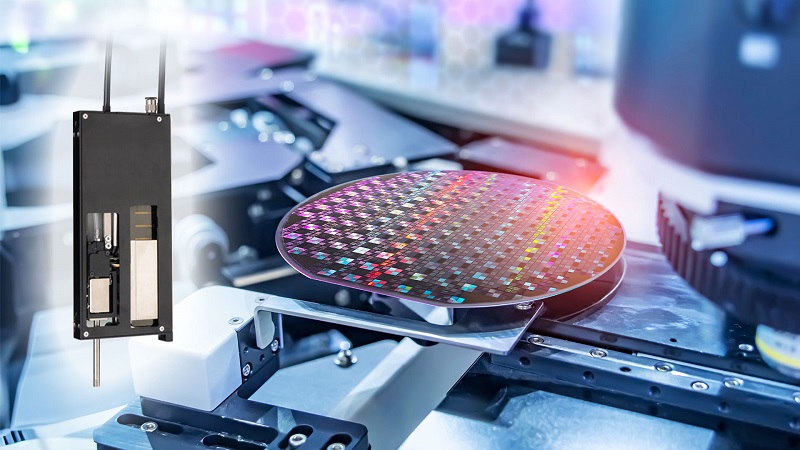

Delta’s Linear Pocket Actuator LPL Series integrates linear motors, linear encoders, and rails in one unit. It not only offers high control precision, lightweight compact size, and easy installation but also perfectly meets customers' inspection needs.