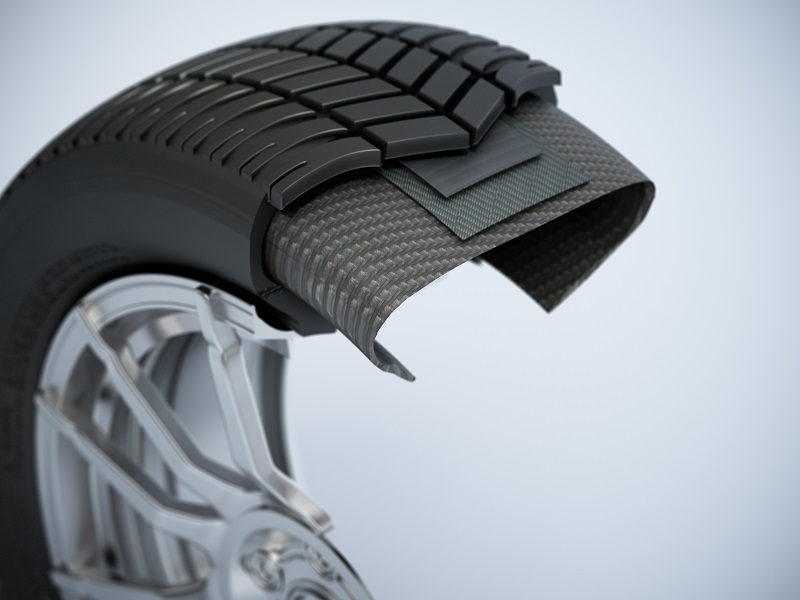

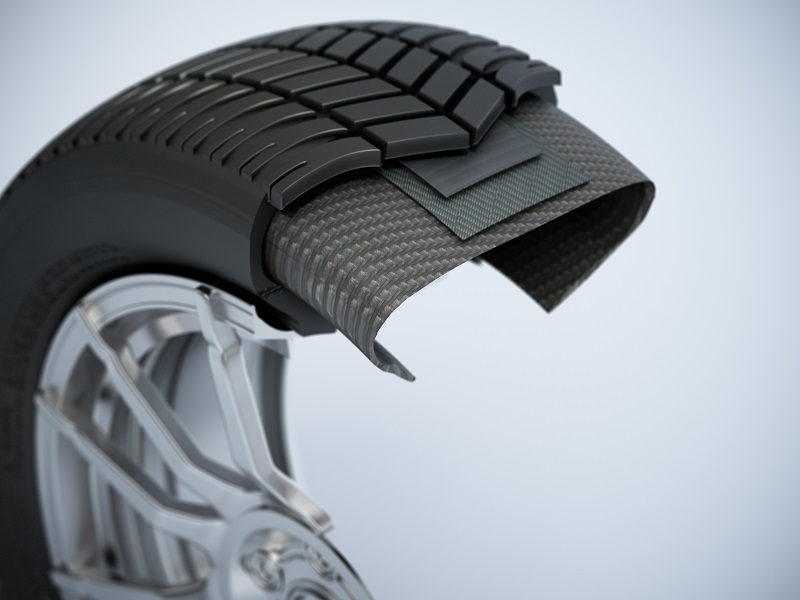

Tires are an essential component of vehicles, designed to provide traction, support vehicle weight, absorb vibrations, and reduce shocks during motion.

The tire cord is the core material that makes up the tire's skeleton. Its primary functions are to stabilize the overall tire structure, strengthen the tread to resist punctures, and absorb road bumps.

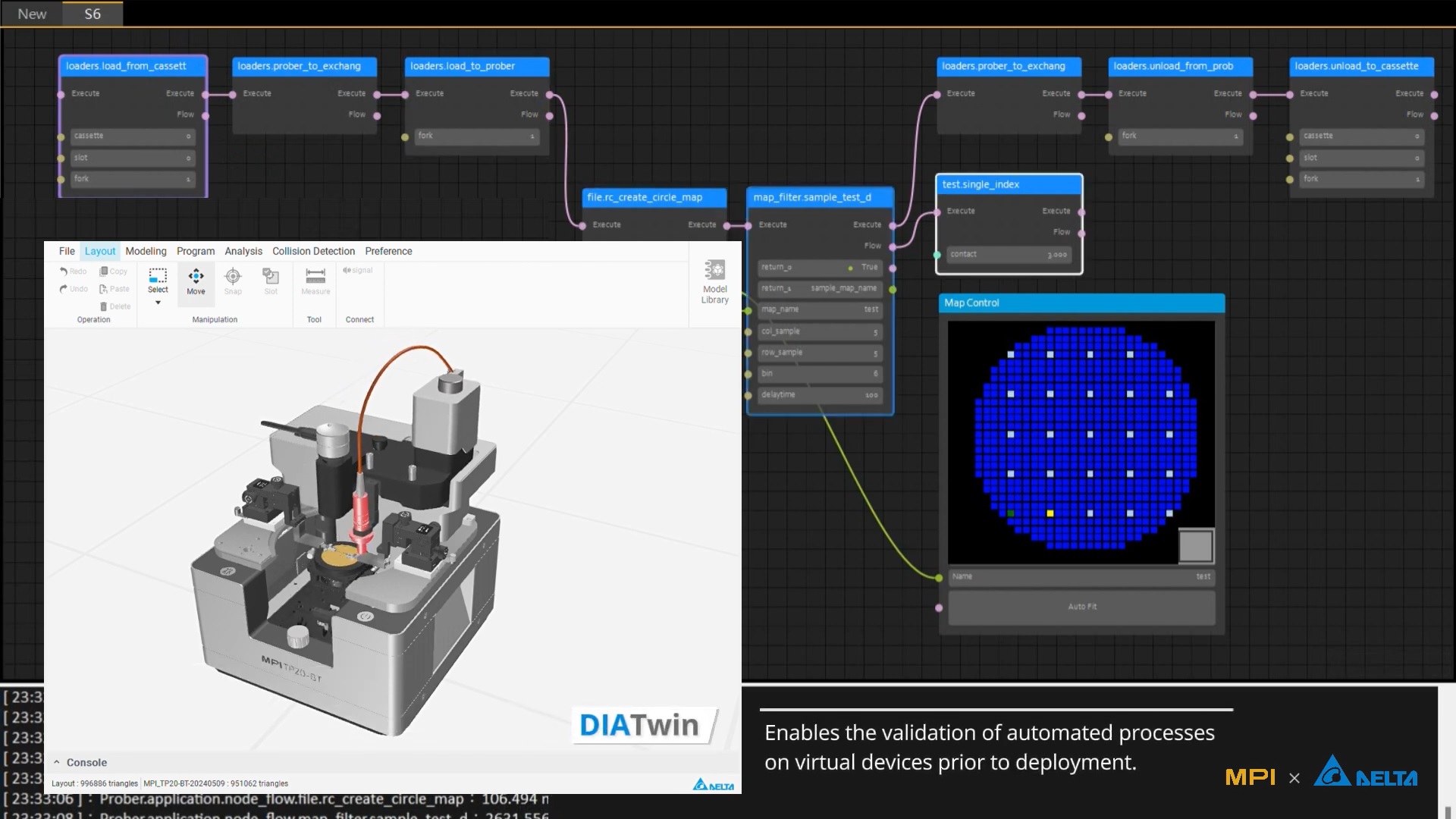

Delta’s Automatic Tire Cord Splicing System Solution highly integrates self-developed products, including drives, servo systems, SCARA robots, industrial cameras, PLCs, HMIs, and a machine vision platform.