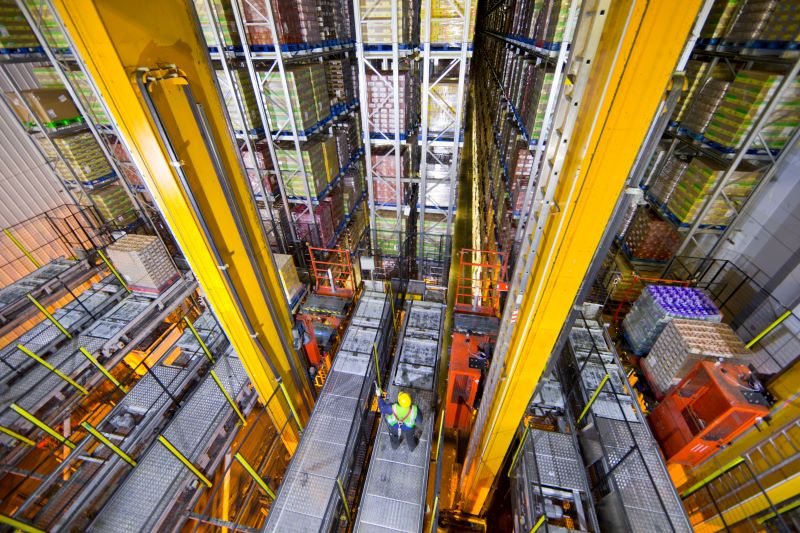

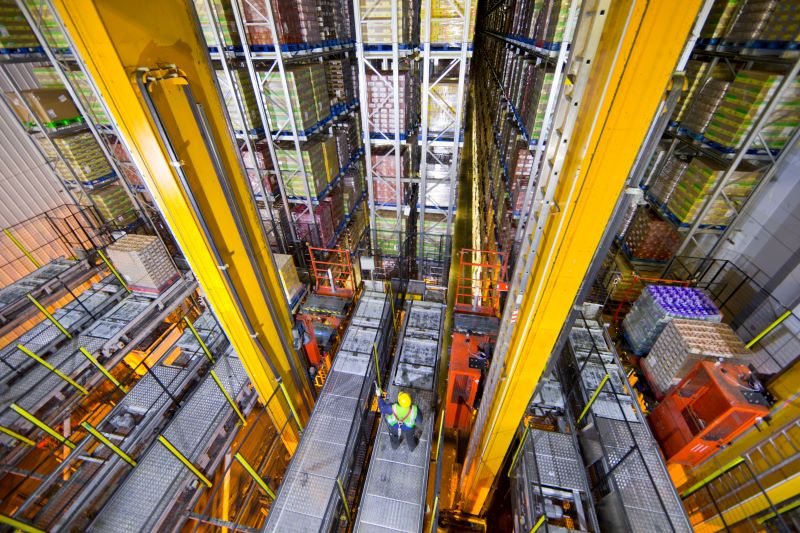

The AS/RS system comprises multiple aisles of closely installed large-scale racks with limited lighting, and relies on automated stacker cranes to store and retrieve goods on pallets or in bins along the rails built between the rack structures.

Delta’s 3D ToF Smart Camera DMV-T achieves high-speed imaging, precise detection, positioning, and recognition for various applications in environments with very low light.

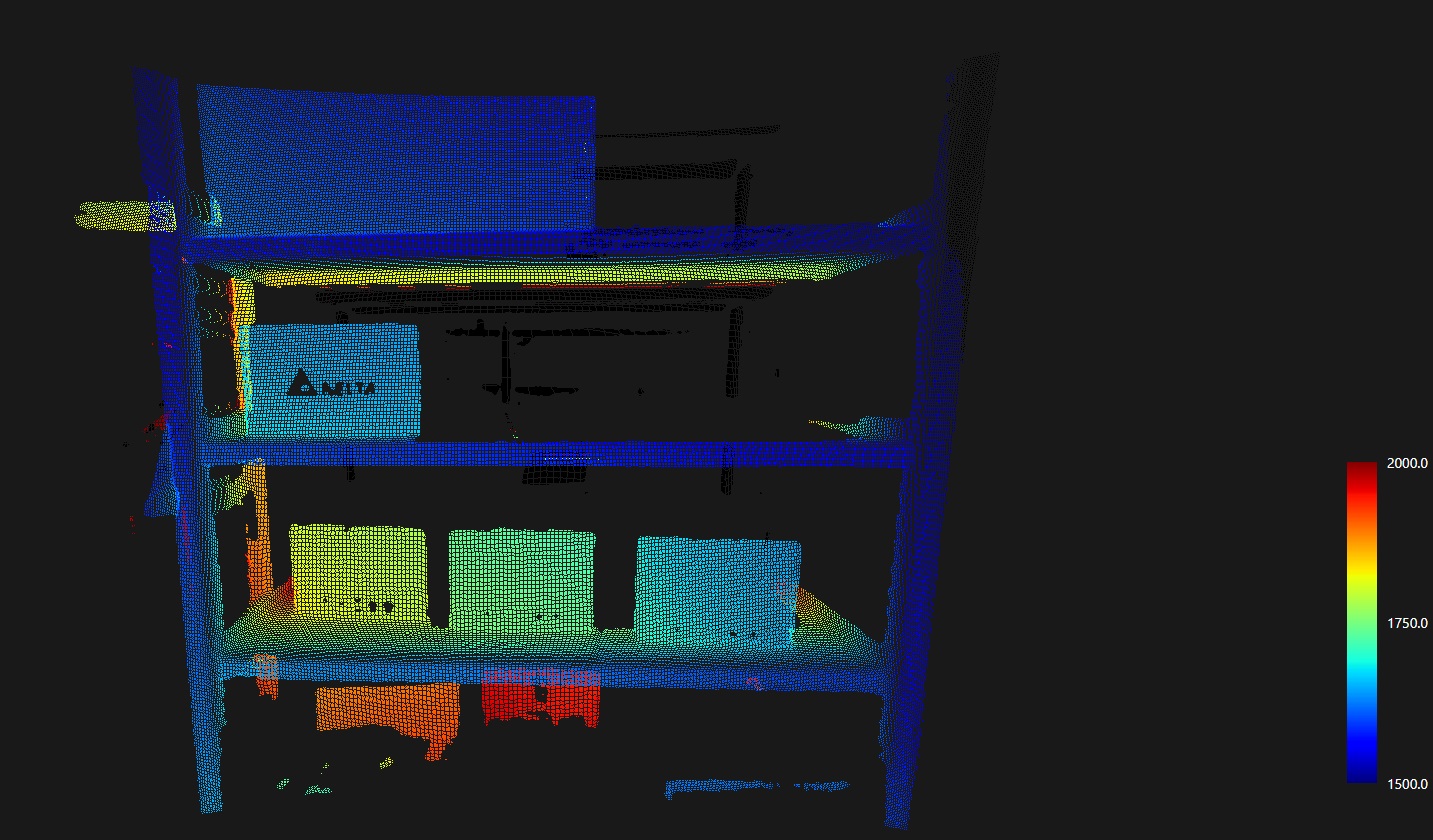

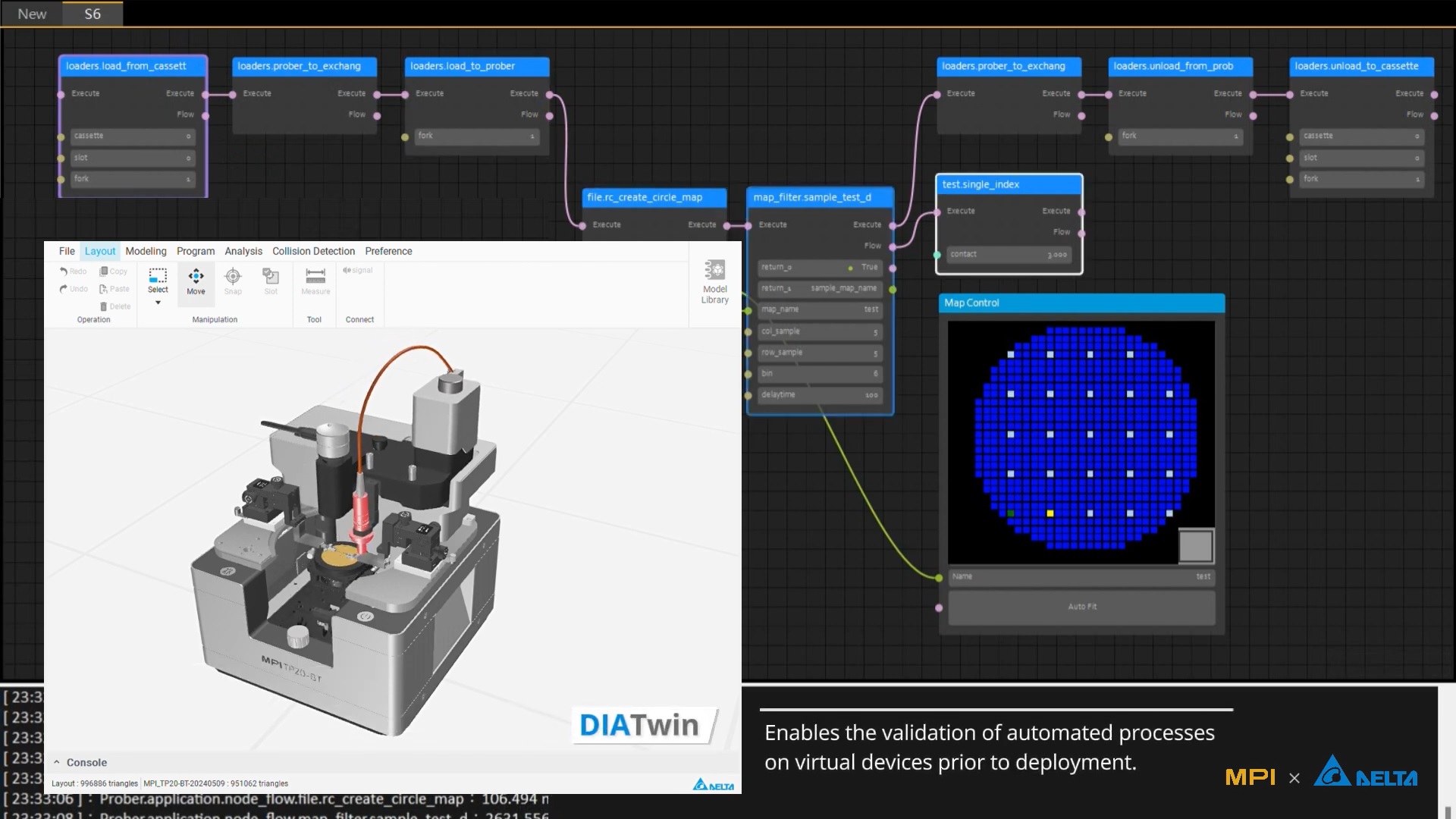

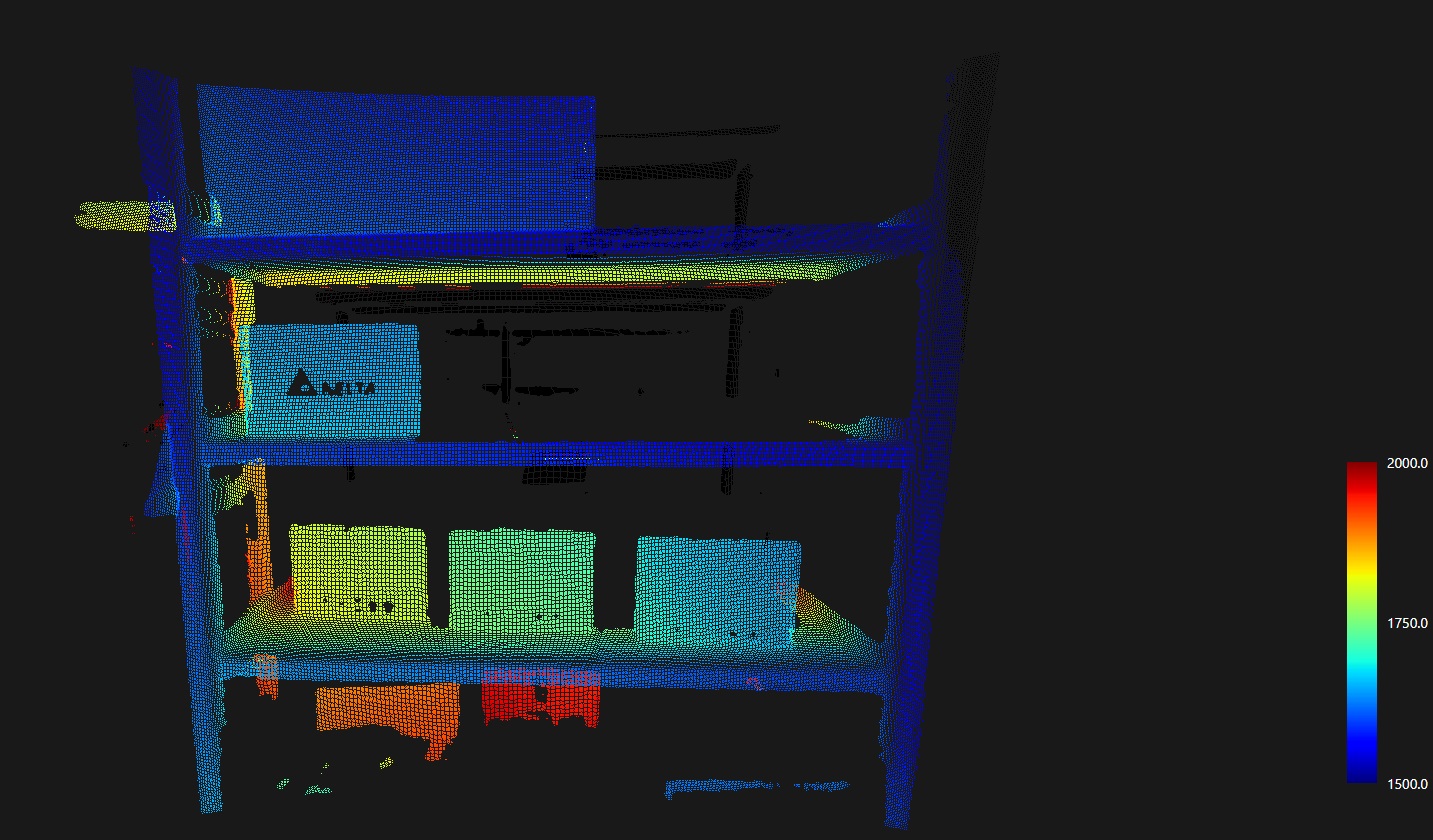

The DMV-T’s quality imaging, when paired with Delta’s machine vision software DIAVision, can detect the presence, depth and dislocation of stored goods and adjust the stacker crane’s movement to enhance retrieval performance and reduce maintenance costs.