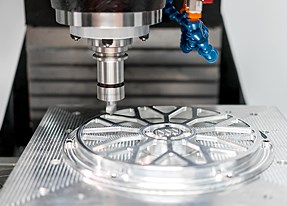

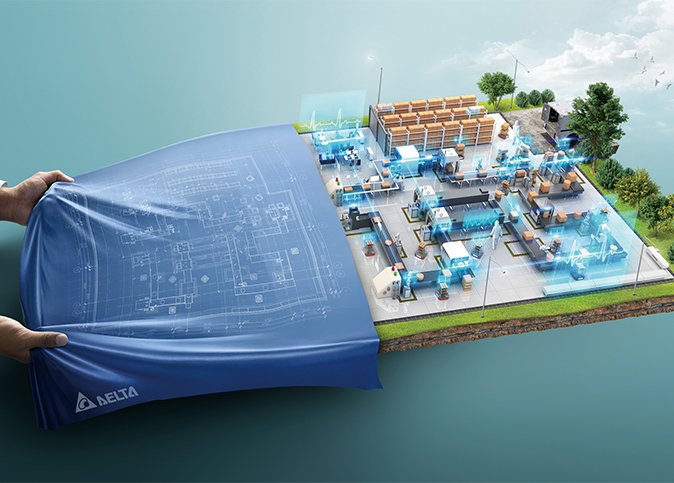

With robust R&D capability and solid industry experience for more than 20 years, Delta offers industrial automation products and solutions with superior quality, reliability and precision that find application in a broad range of industries, including electronics, components, photoelectric panels and food & beverages. We are dedicated to providing innovative and reliable smart, green manufacturing solutions for global customers, keeping our promise of “Automation for a Changing World”.

CONTACT

- Smart Manufacturing Solutions

Email:IABG.FAS@deltaww.com - FMCS & EMS

Email:IABG.ISP@deltaww.com - Smart Equipment

Email:ambu@deltaww.com - Industrial Automation Products

Tel : +886-3-362-6301 (Ext. 7113)

Email:ia.sales@deltaww.com

Email:RAYMOND.JH.LEE@deltaww.com