Delta Electronics exhibited at the China International Industry Fair 2014 (CIIF 2014) in Shanghai from November 4th~8th with the theme “Smart Factory and Management Visualization”. Delta displayed solutions for industrial automation, intelligent monitoring and display management, high-efficiency power supply, power quality, and data centers.

Integrated System Solution and SCARA for Smart Factory and Management Visualization

For “Smart Factory and Management Visualization”, Delta's Industrial Automation Business Group (IABG) presented its Integrated System Solution and Selective Compliance Assembly Robot Arm (SCARA), which both represent breakthroughs for Delta's automation development.

Delta's Integrated System Solution performs facility control, system monitoring and control, and data management. It adopts power meters, AC motor drives, programmable logic controllers (PLCs), industrial Ethernet switches and energy-saving technology to improve the power efficiency of facilities.

Delta also integrates supervisory control and data acquisition (SCADA ) configuration software and an energy management system to collect and analyze the power consumption of various facilities. Users can precisely master real-time power consumption of facilities, production lines and factory/buildings, and improve power effiency of major facilities according to historical data. Delta also provides energy-saving factory automation solutions that allow users to improve facility operation efficiency, production process and energy efficiency.

Delta's integrated system automation solution helps customers maximize power efficiency, save energy and determine energy management strategies, creating new advanced, smart and green manufacturing that meets Delta's promise of “Smarter. Greener. Together.”

Delta also provided a new solution for production line automation: the Delta SCARA Solution. The SCARA solution features high-speed, high precision, excellent linearity and verticality, and compliance control functions. It increases production efficiency and can improve production quality and yield rate with a machine vision system. Delta's SCARA solution is perfect for application on the production lines of the electronics, rubber and plastic, and packaging industries.

During the event, Delta presented its SCARA solutions in two live demos with controllers and machine vision. The two demos demonstrated compliance control for components insertion and simulate the production processes of gluing, coating and polishing. The demos were the focus for media and visitors, and were introduced by China's magazines and other press.

During the Delta CIIF 2014 Press Conference on the opening day, IABG's General Manager Simon Chang introduced Delta's SCARA to more than 100 news and media companies. He said, “Industrial robots such as SCARA are the crucial solutions for industrial upgrades and labor shortages. Now, industrial robots are mainly applied in heavy industries. As technology develops faster every day, I'm sure we'll soon see more in the lighting and electrical industries.”

Delta Chairman Yancey Hai highlighted the importance of Delta SCARA during the press conference, “Delta's SCARA and control system help customers effectively control costs and save energy. They are the realization of a smart automation solution, and also fulfill Delta's mission “To provide innovative, clean and energy-efficient solutions for a better tomorrow.””

In addition to integrated factory automation solutions, Delta also exhibited advanced, practical and energy-saving solutions, including motion control solutions, AC motor drive applications and power quality solutions for mechanical, manufacturing, construction and the public construction fields. Many reporters from the local media visited Delta's stand to interview IABG's management team and report on IABG's vision and development, as well as Delta's automation products and applications in various industries.

Gathering for a Common Vision with Sales and Distributors

During the show, Delta organized its “Delta VIP Partner Autumn Gathering” for Chinese partners and “Delta Russia and CIS Partner Conference 2014” for Russian distributors. The partners and distributors visited Delta's R&D center and factory at its Wujiang Plant, Delta's China headquarters in Shanghai, and Delta's stand at CIIF 2014. They also participated in seminars and meetings to enhance their knowledge of the IABG's new automation solutions and sales strategies.

Delta VIP Partner Autumn Gathering

Delta's IABG has hundreds of distribution partners from all around China attend the “Delta VIP Partner Autumn Gathering” annually to share and exchange product sales information. This year, distributors from 27 companies attended the “Delta VIP Partner Autumn Gathering”. They visited Delta's stand at CIIF 2014 and had meetings with Delta and the IABG management team.

As Delta is promoting integrated automation solutions for target industries, the IABG held its “Delta Power Quality Improvement Solution and Energy-saving Industrial Solution Seminar” and invited nearly 40 leading business executives from various industries. They learnt about Delta's power quality solutions and energy-saving industrial solutions and discussed future business opportunities.

Delta Russia and CIS Partner Conference 2014

Since Delta is currently developing the automation markets of Europe, Africa, the Middle East, and Russia, the IABG also held “Delta Russia and CIS Partner Conference 2014” during CIIF 2014.

Through the conference, the IABG shared Delta's latest automation products, technology and solutions, as well as its strong brand image and company philosophy to more than 30 Russian partners. They also paid a visit to Delta's Wujiang R&D Center and factory and were impressed by Delta's development and production capabilities. Some of the Russian partners expressed their interest in Delta's sales strategies in China and their willingness for further cooperation.

Multiple Awards Proves Outstanding Development Capabilities

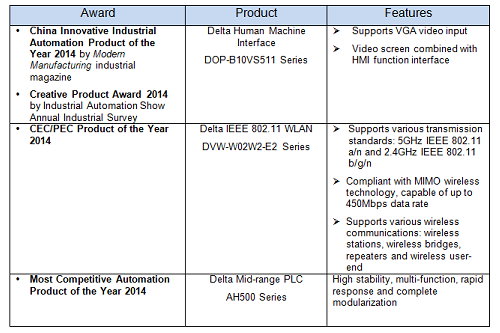

Due to Delta's strong R&D teams, three of Delta's industrial automation products won awards for innovation, excellent functions, and energy-saving capabilities. Delta was once again chosen to become the “Brand of Excellence”.

Delta's award winning automation products include:

Delta is devoted to enterprise sustainability and product and technology innovation, investing over 5% to 6% of its annual sales revenue in R&D. As a model automation company, Delta highly values corporate social responsibility and earns credits for company management, enterprise culture and service system build-up.

Through continuous development and innovation, Delta has comprehensive automation product lines and has started to conduct system integration to provide total solutions for a variety of industries. For now, Delta is integrating its automation products, software and technology for “Smart Factory” with intelligent manufacturing and visual management. At this year's CIIF, Delta set up a new milestone for future development and opened up a wider road to industry upgrades.